The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Feed Materials Production Center (FMPC) EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Feed Materials Production Center (FMPC)

Also Known As: Fernald, Fernald Environmental Management Project (FEMP), FERMCO, Fernald Environmental Project, and NLO.

State: Ohio

Location: Fernald

Time Period: 1951-present

Facility Type: Department of Energy

Facility Description: The Feed Materials Production Center (FMPC) at the Fernald site was established by AEC in 1951 to convert depleted uranium, natural uranium, and low-enriched uranium compounds into uranium metal and to fabricate uranium metal into feed stock for fuel and target elements for reactors that produced weapons-grade plutonium and tritium. The Fernald Plant, operated by National Lead of Ohio (NLO), along with the Weldon Spring Plant in Missouri, were feed materials plants built by the AEC in the 1950s to supply fuel to the increasing number of nuclear reactors located at Hanford and Savannah River. Production operations at the Fernald site continued until July 10, 1989, when they were suspended by the Department of Energy (DOE). DOE formally shut down the facility on June 19, 1991. During its production mission, the Fernald site produced over 225 million kilograms (500 million pounds) of high-purity uranium products to support United States defense initiatives.

Throughout the course of its operations, the potential for beryllium exposure existed at this site, due to beryllium use, residual contamination, and decontamination activities.

CONTRACTORS: Fluor Fernald (1992-present); Westinghouse (1985-1992); National Lead of Ohio (1951-1985)

Listing:

Feed Materials Production Center (FMPC) is listed as Department of Energy (DOE) site under the EEOICPA.

Special Exposure Cohort(SEC) Classes:

All employees of DOE, DOE contractors, or subcontractors who worked at all locations at the Feed Materials Production Center (FMPC) in Fernald, Ohio, also known as the Fernald Environmental Management Project (FEMP), from January 1, 1968, through December 31, 1978, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more classes of employees included in the Special Exposure Cohort.

All employees of the Feed Materials Production Center (FMPC) in Fernald, Ohio, who were not employed by National Lead of Ohio, NLO, or the Department of Energy or its predecessor agencies, who worked at FMPC from January 1, 1951, through December 31, 1983, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work

Note: This class was established from Petition 46

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the Feed Materials Production Center (FMPC) in Fernald, Ohio, from January 1, 1954, through December 31, 1967, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

Note: This class was established from Petition 46

History:

The Feed Materials Production Center (FMPC) is located northwest of Cincinnati in Fernald, Ohio. The facility received its name because the uranium fuel cores it produced were used to “feed” the Atomic Energy Commission’s reactors at Oakridge, Savannah River, and Hanford. FMPC produced about 170,000 metric tons of uranium metals from 1951 to 1989. Because of its location, it is also known as Fernald. FMPC also was the central repository for the U.S. thorium supply.

The Fernald Closure Project started in 1990 and was overseen by the Department of Energy. The site underwent an environmental cleanup and the waste was buried. However, because of the high level of contamination, the site remains unfit for human habitation and will most likely have to be closely monitored forever.

Compensation:

As of 01/08/2023, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Feed Materials Production Center is $411,622,238. Click here for a current accounting of compensation paid to former FMPC Workers under the EEOICPA.

Feed Materials Production Center Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*From the Fernald Closure Project:

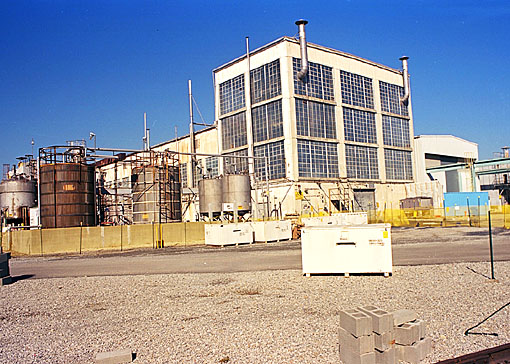

Construction of one of the production facilities (6335-109)

The 1,050-acre Feed Materials Production Center (Fernald site) was designed as a large-scale, integrated facility capable of converting uranium ore and recycled material into uranium metal through a series of chemical and metallurgical conversions. Approximately 136 acres in the center of the site were used in the actual production process; the remaining acreage included administration facilities, laboratories, waste storage areas, and buffer land. The production area contained 10 primary plants, each with a specific mission to support the uranium metal production process.

Pilot Plant, the UF6 to UF4 Reduction Facility:

Pilot Plant, the UF6 to UF 4 Reduction Facility (6333-1).

The Pilot Plant became the first plant to operate in October 1951. The plant served as an operating prototype of all phases of Fernald’s uranium metal production process. After the shutdown of Plant 7 in 1956, the Pilot Plant converted uranium hexafluoride to uranium tetrafluoride, called green salt, for use in the metal production process. The plant was also used to coat metal-casting crucibles by plasma spray to minimize carbon pickup in uranium metal products. In the early 1960’s, workers developed a high-purity melting and casting technique in the Pilot Plant, and thorium production operations resumed for several years. Fernald completed safe shutdown of the Pilot Plant in June 1996, and plans to complete demolition of the plant in 2003.

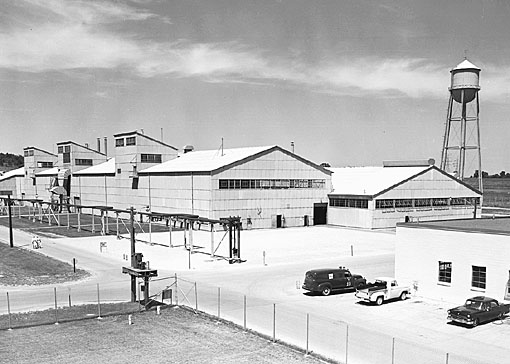

Plant 1, the Sampling Plant:

Plant 1, the Sampling Plant (89-366-1).

Plant 1, the Sampling Plant (89-366-1).

Plant 1 operations began in December 1953. The plant was used to weigh, sample, classify and sort (by uranium content) incoming raw material from off-site sources and process residues from on-site operations. Shortly after coming on line, the AEC designated Plant 1 the official AEC sampling station. Prior to this, sampling was completed at the New Brunswick Laboratory in Middlesex, N.J. The Plant 1 Complex included the Plant 1 Pad, a concrete pad used to store drums of incoming material and process waste, and the 14 Plant 1 Ore Silos which were used to store bulk processed raw materials. In 1989, site management shut down all plant operations to focus on environmental compliance and waste management issues. Fernald completed safe shutdown of Plant 1 in August 1995, and imploded the steel structure in February 1997. The Plant 1 Ore Silos were dismantled in 1994 as part of a CERCLA removal action.

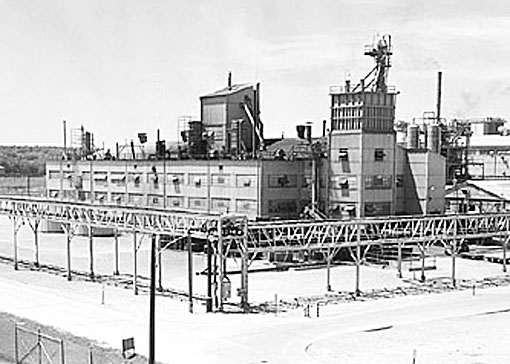

Plants 2 and 3, the Ore Refinery Plants:

Plants 2 & 3, the Ore Refinery Plants (89-148-1).

Plants 2 & 3 operations began in December 1953. The plants were used to convert impure uranium feed material and recycled residue to high purity uranium trioxide following a three-step procedure (digestion, extraction, denitration) involving chemical and thermal processes. Plants 2 & 3 were originally designed to process 4,570 metric tons of uranium per year, but were later expanded to double their capacity. In 1962, site management placed Plants 2 & 3 on standby when refining operations were consolidated at the Weldon Spring site near St. Louis, Mo. For the next few years, Plants 2 & 3 operations processed only scrap feed until 1966, when they were reactivated following the shutdown of Weldon Spring. Plants 2 & 3 operations continued through 1989 when site management shut down all plant operations to focus on environmental compliance and waste management. Fernald completed safe shutdown of Plant 2 in December 1998 and Plant 3 in September 1997. Fernald plans to complete demolition of Plants 2 & 3 in 2003.

Plant 4, the Green Salt Plant:

Plant 4, the Green Salt Plant (89-319-1).

Plant 4 operations began in October 1953. The plant was used to convert uranium trioxide to uranium dioxide, called brown oxide, by reducing it with hydrogen. The brown oxide was reacted with anhydrous hydrogen fluoride to produce uranium tetrafluoride, called green salt. Green salt was then used in the uranium metal production process that occurred in Plant 5. Plant 4’s production peak occurred in 1958 when it produced nearly 12,000 metric tons of uranium of normal uranium tetrafluoride. A decline in demand caused the facility to operate sporadically from the early 1970s to 1980, when the process was restarted and operated until site management shut down all plant operations in 1989 to focus on environmental compliance and waste management issues. Fernald completed safe shutdown of Plant 4 in October 1995, and imploded the steel structure in August 1996.

Plant 5, the Metals Production Plant:

Plant 5, the Metals Production Plant (479-9).

Plant 5 operations began in May 1953. The plant contained large furnaces that were used to convert green salt to uranium metal derbies by a thermite reduction process using magnesium metal granules. The uranium derbies were then loaded into graphite cubicles, vacuum melted in induction-heated furnaces and poured into molds to create ingots. The ingots were weighed, sampled, washed and stored for further processing in Plant 6. From 1953 through 1956, derby and ingot production rose steadily. In later years production fluctuated. Fernald completed safe shutdown of Plant 5 in March 1997, and completed demolition in 2001.

Plant 6, the Metals Fabrication Plant:

Plant 6, the Metals Fabrication Plant (479-4).

Plant 6 operations began in the summer of 1952. The plant was used to fabricate ingots into finished uranium cores. The ingots were heat-treated to improve their strength and grain structure and shaped into oval billets in the rolling mill. Some billets were shipped off site for extrusion into tubes of various dimensions, and later returned to the Fernald site where they were machined, cut to specific slug sizes, and shipped to other production sites. In 1971, Fernald shut down the rolling mill operation and all machined ingots were heat-treated and shipped to Reactive Metals, Inc. (RMI) in Ashtabula, Ohio, for extrusion into tubes. Fernald completed safe shutdown of Plant 6 in December 1998, and demolition in 2002.

Plant 7, the Hexafluoride Reduction Plant:

Plant 7, the Hexafluoride Reduction Plant (479-13).

Plant 7 operations began in June 1954. The plant was used to convert uranium hexafluoride to green salt using the same process as the Pilot Plant. The green salt was used in Plant 5 to produce uranium metal. After only two years of operation, the AEC directed the shutdown of Plant 7 because a similar processing plant was operating in Paducah, Ky. For the next 13 years, site management considered several proposals for the idle facility, but none of the proposals were accepted. In 1969, all equipment was excessed and sold, and the building was used to store drums of green salt and empty containers. In 1994, Fernald imploded the Plant 7 steel structure as a CERCLA removal action to reduce the potential for contamination exposure to workers, the public and environment. Plant 7 was the first major production plant demolished, requiring two separate implosions to bring the seven-story structure to the ground.

Plant 8, the Scrap Recovery Plant:

Plant 8, the Scrap Recovery Plant (479-6).

Plant 8 operations began in November 1953. The plant was used to convert scrap uranium metal and metal-bearing waste from off-site sources and Fernald operations into black oxide. The black oxide was then sent to Plant 1 as a feed material. Because uranium was such a valuable material, Fernald recycled uranium contained in waste streams for reuse. Machining chips and turnings were compacted into briquettes in Plant 6, re-melted in Plant 5 and sent back to Plant 8 for uranium recovery. During the 1970s, Plant 8 operated on an as-needed basis. In 1980, it returned to full operations until 1989, when site management shut down plant operations to focus on environmental compliance and waste management issues. Fernald completed safe shutdown of Plant 8 in March 1998, and plans to complete demolition in 2003.

Plant 9, the Special Products Plant:

Plant 9, the Special Products Plant (6333-15).

Plant 9 operations began in October 1954. Originally, it was used to produce thorium metal until 1956, when interest in thorium metal started to decline. The plant was used to cast special oversized enriched uranium ingots (larger than those processed in Plants 5 and 6) into billets. All Plant 9 operations were discontinued in 1989, when site management shut down plant operations to focus on environmental compliance and waste management issues. In the 1990s, Plant 9 housed the Minimum Waste Stabilization Project that investigated the use of vitrification to stabilize waste sludges and other contaminated material. Fernald completed safe shutdown of Plant 9 in January 1996, and completed demolition in 1998.

Videos:

A more detailed explanation of the activities at FMPC can be seen below:

DOCUMENTS:

NIOSH SEC Petition Evaluation Reports

Petition 46 (Jan 1, 1951 to Dec 31, 1989)

SEC Petition Evaluation Report, Petition SEC-00046, Report Rev # FINAL Report Submittal Date: _10-25-06

Technical Basis Documents

Site Profile

Feed Materials Production Center – Introduction

Effective Date: 08/05/2016

Feed Materials Production Center – Site Description

Effective Date: 03/31/2014

Fernald Environmental Management Project – Occupational Medical Dose

Effective Date: 01/02/2014

Feed Materials Production Center – Occupational Environmental Dose

Effective Date: 09/22/2016

Feed Materials Production Center – Occupational Internal Dose

Effective Date: 03/30/2017

Feed Materials Production Center – Occupational External Dose

Effective Date: 03/25/2014