The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren.

Are you eligible for compensation? If you or a family member worked at this or another AWE or DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Western New York Area:

Ashland Oil

Bethlehem Steel

Bliss + Laughlin Steel

Carborundum Company

Crucible Steel Co.

Electro Metallurgical

Hooker ElectrochemicalIthaca Gun Co.

Ithaca Gun Co.

Lake Ontario Ordnance Works

Linde Air Products

Linde Ceramics Plant

Seaway Industrial Park

Simonds Saw And Steel Co.

Titanium Alloys Manufacturing

University of Rochester Atomic Energy Project

Utica St. Warehouse

*Note: Special Exposure Cohort (SEC) facilities appear in bold

_________________________________________________________________

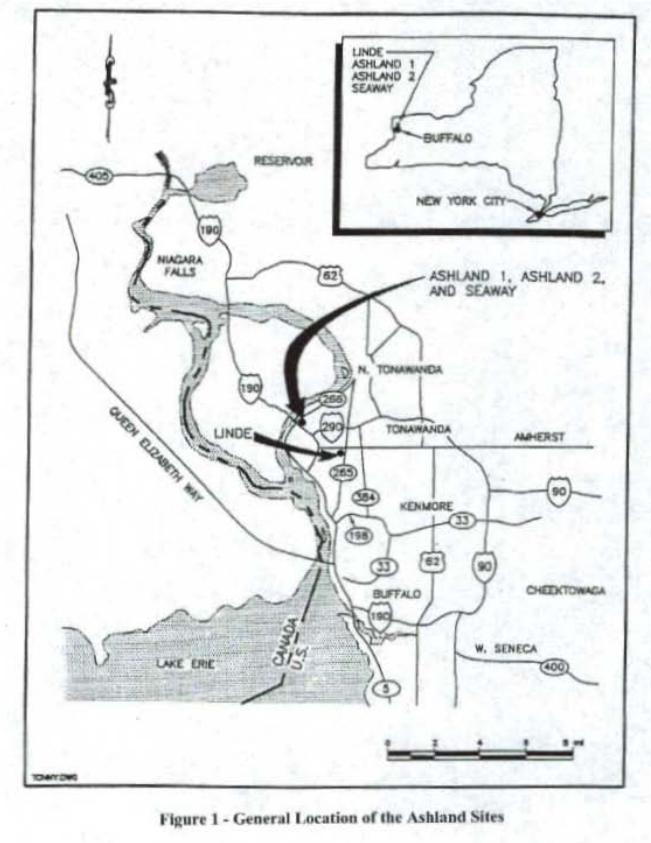

Ashland Oil

Also Known As: Ashland #1, Ashland #2, Ashland Oil Company, Haist Property, E. Haist and co owners

State: New York

Location: Tonawanda

Time Period: AWE 1944-1960; 1974-1982; Residual Radiation 1961-1973; 1983-2006

Facility Type: Atomic Weapons Employer

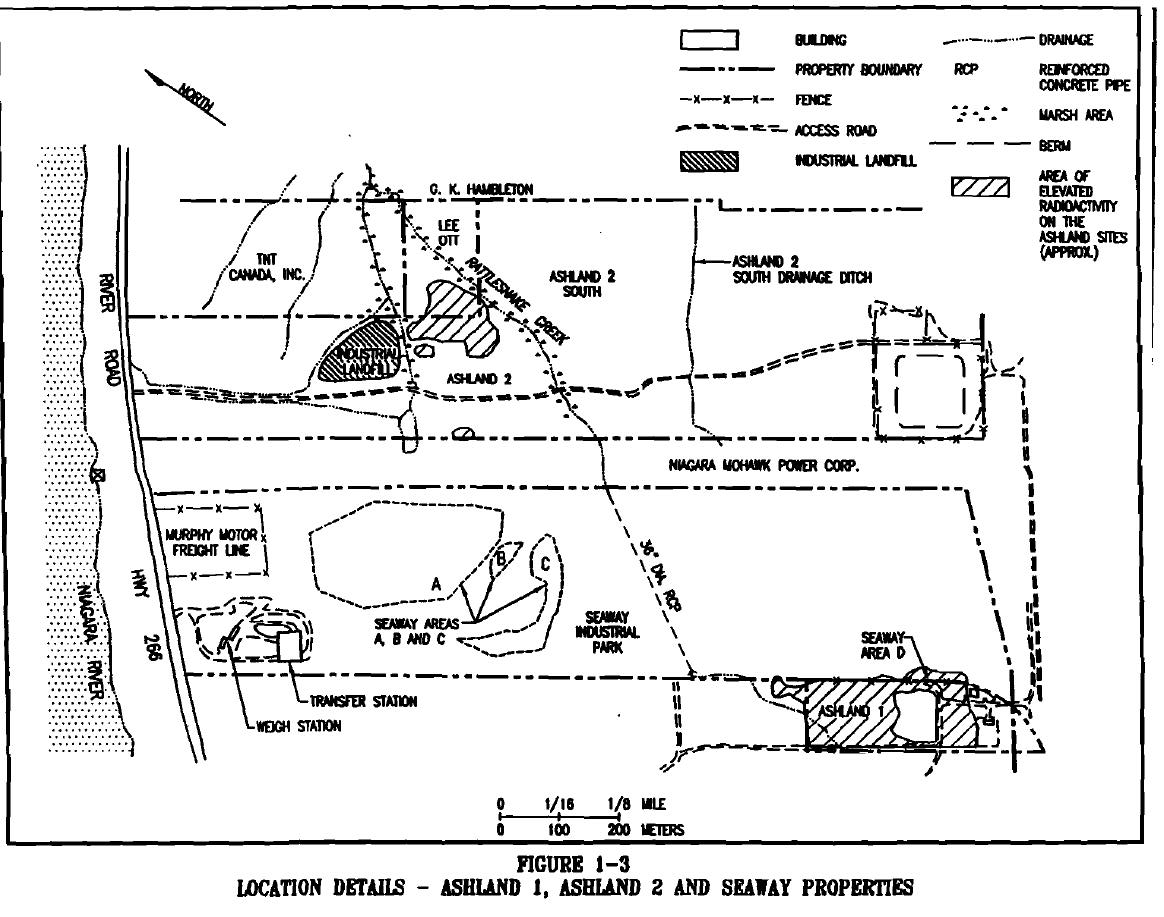

Facility Description: In August 1944, the Manhattan Engineer District purchased the Ashland #1 property, formerly known as the Haist Property, for use as a disposal site for approximately 7,250 metric tons (8,000 tons) of uranium ore tailings and concentrate refining residues generated at the nearby Linde site. When the uranium residues were transported to the Ashland #1 site, they were spread over two-thirds of the property to estimated depths of 0.3 to 1.5 meters (one to five feet). In 1960, the Atomic Energy Commission determined that the levels of residual radioactivity atAshland #1 site were below then current criteria and released the land as surplus. The Ashland Oil Company eventually acquired the property. From 1957 to 1982, the Ashland Oil Company used a portion of the Ashland #2 site as a landfill for disposal of general plant refuse and industrial and chemical wastes and materials. Between 1974 and 1982, Ashland Oil transported from the Ashland #1 site an unknown quantity of soil mixed with radioactive residues to the Ashland #2 landfill.

Although the Ashland Oil facility was designated for the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1984, no actual remediation under this program occurred prior to its transfer to the Army Corp.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

*Site Description and History:

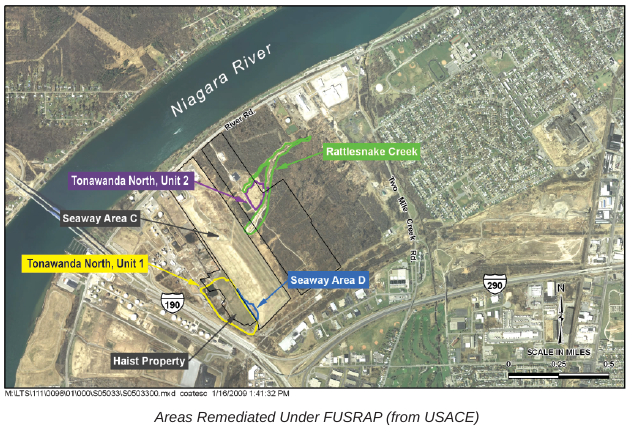

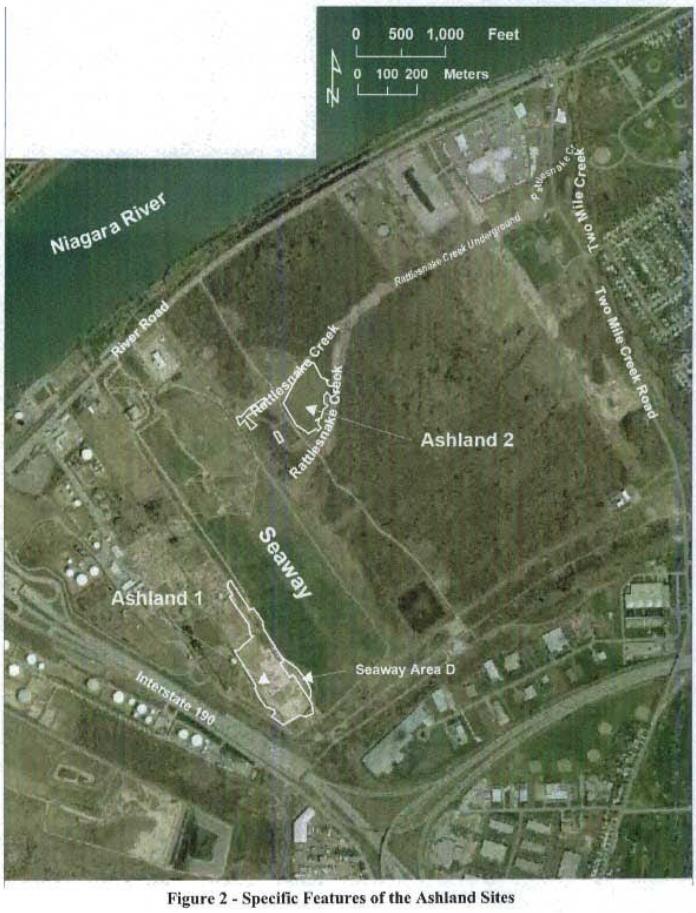

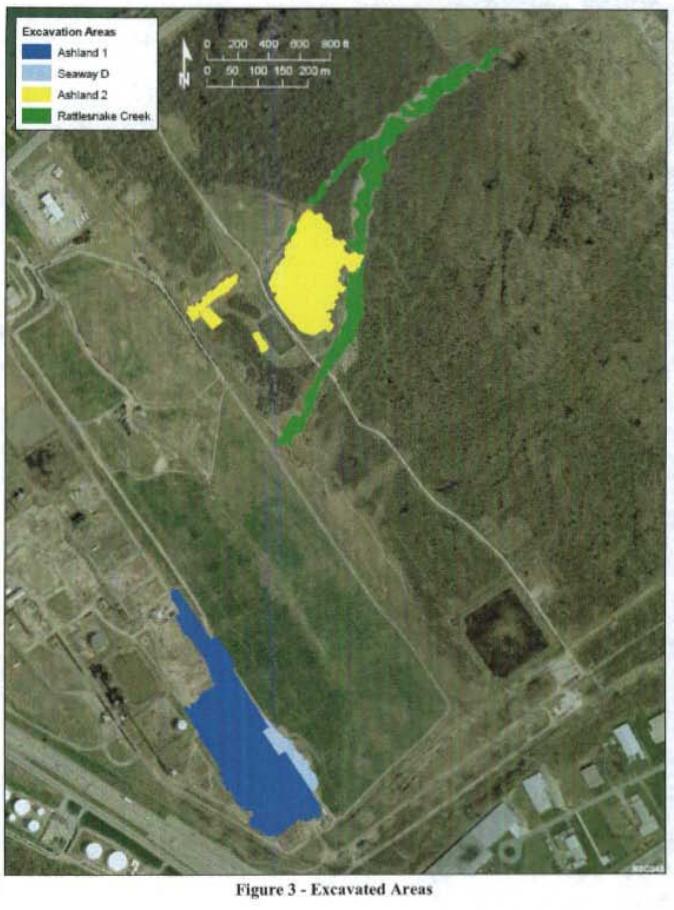

The Tonawanda North, New York, Site, Units 1 and 2,formerly called the Ashland Oil #1 and #2 sites, are located in Tonawanda, New York, a suburb of Buffalo. The Tonawanda North site comprise three areas: Unit 1 (Ashland Oil #1, which Includes Seaway Area D), Unit 2 (Ashland Oil #2 and Rattlesnake Creek), and Unit 3 (Seaway Area C). Only Units 1 and 2 have been closed and transferred to the U.S. Department of Energy (DOE) Office of Legacy Management (LM) for long-term surveillance and maintenance.

As part of the nation’s early atomic energy program, the former Linde Air Products Division of Union Carbide Corporation processed uranium ores at its facility in Tonawanda. This work was conducted under contract to the Manhattan Engineer District (MED) from 1942 to 1946.

From 1944 to 1946, about 8,000 tons of wastes from processing low-grade uranium ore were transported from Linde to a 10-acre area known then as the Haist property, now called Tonawanda North, Unit 1. In 1960, the property was transferred to the Ashland Oil Company for use in the company’s oil refinery activities.

The Ashland Oil Company used a portion of what is now Tonawanda North, Unit 1 as a landfi ll for disposal of general plant refuse and industrial and chemical by-products. In 1974, the Ashland Oil Company constructed a drainage ditch and a bermed area for two petroleum product storage tanks on Tonawanda North, Unit 1. Soil removed during construction contained radioactive residues, and the Ashland Oil Company transported the contaminated materials to the Seaway Landfill and Ashland Oil #2 sites for disposal. In 1982, Ashland Oil closed the industrial landfill and covered it with clay and soil; the property became covered with grass and shrubs over time.

The primary radioactive materials at the Ashland Oil #1 and #2 sites were uranium-238, radium-226, thorium-230, and their decay products. Some chemical residues from MED activities were also present. DOE determined that the site was eligible for cleanup under the Formerly Utilized Sites Remedial Action program (FUSRAP) in 1984. A Record of Decision for the Ashland Oil #1, Seaway Area D, and Ashland Oil #2 sites was signed on April 20, 1998. Cleanup at the Ashland Oil #2 site was completed in 1999; more than 52,000 tons of material was excavated and shipped offsite for disposal. Cleanup at the Ashland Oil #1 site was completed in 2003; 173,000 tons of material was excavated and shipped offsite for disposal.

Results of sampling conducted by the U.S. Army Corps of Engineers (USACE) during cleanup of the Ashland Oil #2 site indicated that historical activities had contaminated portions of nearby Rattlesnake Creek, and additional cleanup would be necessary. An Explanation of Significant Differences was issued in 2004 to include Rattlesnake Creek in the Ashland Record of Decision. Remediation of Rattlesnake Creek began in May 2005 and was completed in September 2005. More than 33,000 tons of material was excavated and shipped offsite for disposal. The cleanup of Rattlesnake Creek completed the remediation of all areas included in the 1998 Record of Decision. USACE officially observed the completion of the work at the sites on September 14, 2006.

Listing:

Ashland Oil is listed as an Atomic Weapons Employer (AWE) under the EEOICPA.

Compensation:

As of 03/08/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Ashland Oil is $1,517,258.

Ashland Oil Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

**

**Source

***

***Source

_________________________________________________________________

Bethlehem Steel

State: New York

Location: Lackawanna

Time Period: 1949-1952

Facility Type: Atomic Weapons Employer

Facility Description: In 1949, Bethlehem Steel of Lackawanna, New York developed improved rolling mill pass schedules for uranium billets into 1.5- inch rods to be used for reactor fuel rods to later be used at the Fernald plant. Bethlehem also performed uranium rolling experiments to help design the Fernald rolling mill.

NIOSH:

Review of NIOSH Site Profile for Bethlehem Steel Plant, Lackawanna, NY

Listing:

Bethlehem Steel Company is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Special Exposure Cohort (SEC) Classes:

The SEC classes for Bethlehem Steel include:

All Atomic Weapons Employer employees who worked at the Bethlehem Steel Corporation facility in Lackawanna, New York from January 1, 1949 to December 31, 1952, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees in the Special Exposure Cohort.

Job Titles and/or Job Duties in the SEC class include:

Millwrights, welders, electricians, bricklayers, carpenters, all maintenance, testers, rollers, supervisors, crane operators, hookers, clean-up crews, grinders.

History:

Bethlehem Steel in Lackawanna, New York was formed in 1922 by a merger between two steel-producing companies – Lackawanna Steel, located in Western New York, and Bethlehem Steel in Bethlehem, Pennsylvania. The location in Lackawanna was advantageous because of the easy access to Great Lakes shipping and numerous rail lines. Bethlehem Steel became a major supplier of armor plate and ordnance during WWII and in peacetime supplied a variety of structural shapes of steel used in construction.

From January 1, 1949 until December 31,1952, the Lackawanna plant of Bethlehem Steel had a contract with the United States Federal government to roll uranium fuel rods for nuclear reactors. Uranium rolling was carried out in the Ten Inch Bar Mill and Blooming Mill. Workers were unaware of the dangers associated with rolling the heavy metals and were not provided with any protective equipment. Exposure affected many job titles of people working in the Ten Inch Bar Mill and Blooming Mill including millwrights, welders, electricians, bricklayers, carpenters, maintenance, rollers, supervisors, crane operators, hookers, clean-up crews, and grinders.

Compensation:

As of 08/16/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Bethlehem Steel is $232,996,976.

Bethlehem Steel Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Function:

In 1949, AEC contracted with Bethlehem Steel Corporation to develop mill pass schedules for the rolling of natural uranium billets into l-l/2 inch rods to be used for reactor fuel rods. This work was conducted under contracts AT(30-1)-1279 and AT(30-1)-1156 (subcontract with National Lead of Ohio). All work was limited to weekends and involved only the 10-inch bar mill and associated billet preparation and handling equipment. Shipments of uranium billets were received from Mallinckrodt Chemical Company, St. Louis, Missouri,during the week and stored at the mill in rail cars. Following rolling, the material was bundled and returned to AEC. Material accountability procedures required collection of scale, residues, and cropped ends and vacuum cleaning of fine debris for return to AEC. AEC personnel were present during all rolling operations and apparently made radiological surveys and monitored Bethlehem Steel personnel. The project was completed in 1952. The data developed were used in the design of a rolling mill at the Feed Materials Production Center in Fernald, Ohio.

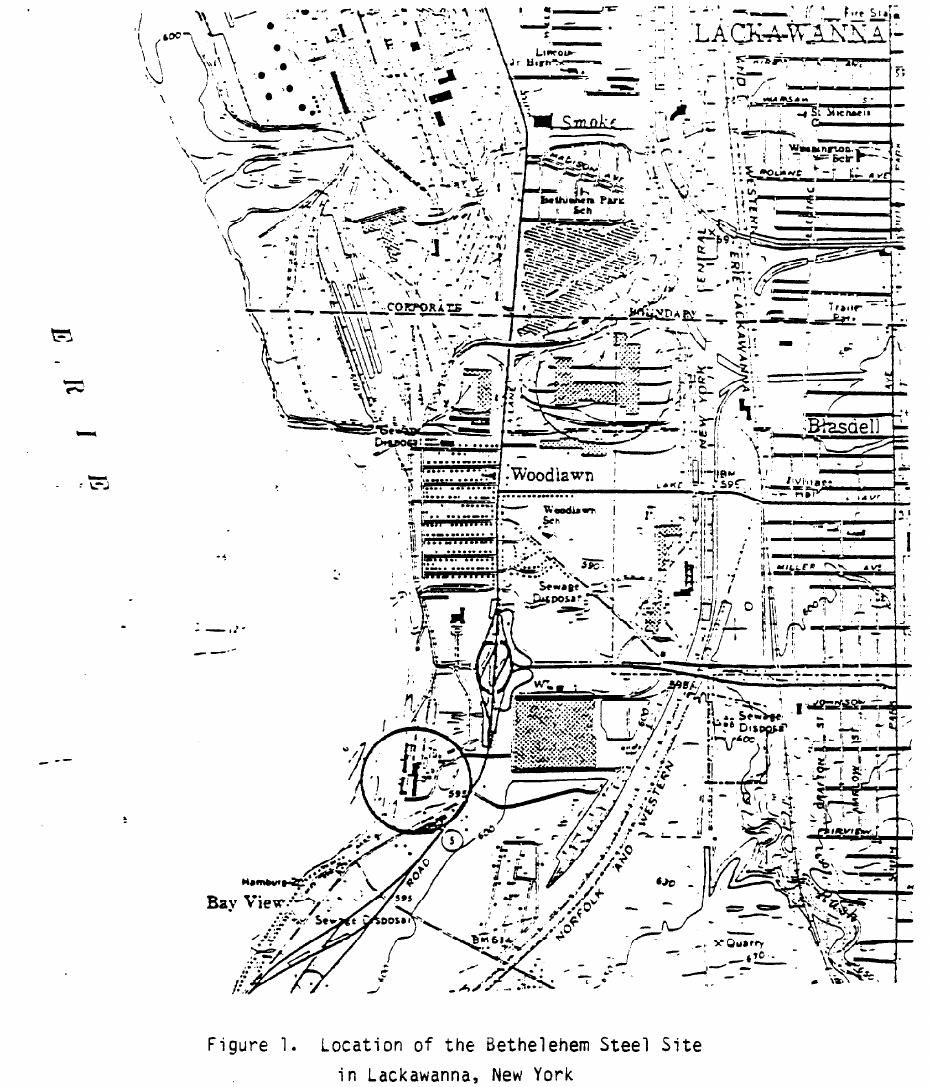

Site Description:

The facilities owned and operated by Bethelehem Steel are located in Lackawanna, New York (see Figure 1). The 10-inch mill was in use for metal rolling operations during the August 1976 radiological screening survey, but has since been taken out of service and dismantled. Ancillary equipment, other than some rolls thought to have been used for uranium work, could not be located.

_________________________________________________________________

Bliss + Laughlin Steel

Also Known As: B & L Steel, Niagara Cold Drawn

State: New York

Location: Buffalo

Time Period: AWE 1951-1952; Residual Radiation 1953-1999

Facility Type: Atomic Weapons Employer

Facility Description: Under contract to the National Lead Company of Ohio (Fernald), Bliss and Laughlin Steel rolled uranium rods for the AEC and also provided uranium slug machining services. Bliss and Laughlin was part of a complex called the Buffalo Works that fashioned components for the early weapons program. The functions were transferred to the Albuquerque South Valley Site in 1952.

Although this site was designated for the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1992, no work occurred under this program prior to its transfer to the Army Corps of Engineers.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above,employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Bliss & Laughlin Steel is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Compensation:

As of 03/15/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Bliss & Laughlin Steel is $2,567,677.

Bliss & Laughlin Steel Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

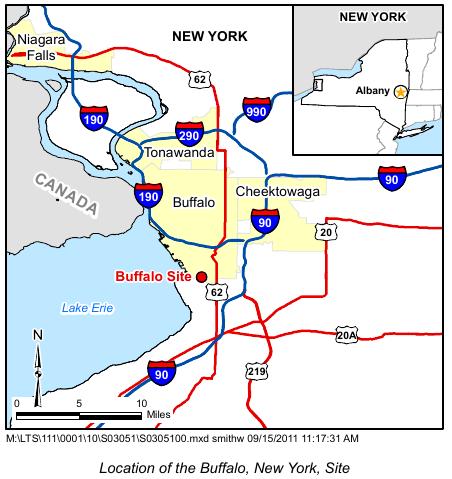

*Site Description and History :

The Buffalo, New York, Site (formerly the Bliss & Laughlin Steel site) is located at 110 Hopkins Street in the southern portion of Buffalo, New York. The site consists of a single, approximately 129,600-square-foot building surrounded by approximately 161,460 square feet of grounds. Used for finishing steel products, the facility is currently owned by the Niagara LaSalle Corporation.

In September and October of 1952, the Bliss & Laughlin Steel Company machined and straightened uranium rods under subcontract to National Lead of Ohio (NLO), who operated the Fernald Site in Ohio under contract to the U.S. Atomic Energy Commission (AEC). These activities at the Buffalo

site generated 53 drums of uranium waste cuttings, which AEC shipped to the Lake Ontario Ordnance Works in Lewiston, New York, for disposal or recycling. At the completion of the uranium-machining operations, NLO conducted radiological surveys of the facility and identified contamination on the machining equipment. These machines were subsequently replaced.

Because no records could be located indicating the radiological condition of the site following uranium machining, the U.S. Department of Energy (DOE) Office of Environmental Restoration and Waste Management recommended a survey of current radiological conditions. A 1992 preliminary survey of the building interior and exterior indicated residual radioactive material on the floor of the Special Finishing Area, a 3,230-square-foot section of the facility where the machining operations were performed. Samples confirmed that the contaminant was processed uranium metal. As a result of the 1992 survey, DOE designated the Buffalo site for inclusion into the Formerly Utilized Sites Remedial Action Program (FUSRAP) in that year.

A subsequent site characterization identified elevated levels of radioactivity on the surfaces of the trusses and the floor of the former Special Finishing Area and on the concrete poured over a trench located west of this area. In addition, contamination in a second trench in the former Special Finishing Area was identified during the remediation process. Remediation of the Buffalo site began in December 1998 and continued through March 1999. Trusses were remediated by scraping, wiping, and then removing the residual dust with a high-efficiency vacuum. Scabbling (a process that grinds and removes the surface of concrete) and jackhammers were used to remove surface contamination from the floor and from the concrete over the trench west of the Special Finishing Area. The second trench and a pit area contained metal shavings and debris, which were removed manually.

The concrete pad covering this trench was jackhammered, and the trench walls and floors were scabbled, jackhammered, and sand-blasted. Approximately 60 cubic yards of construction debris was generated during the decontamination of the trusses, floors, and trenches. This debris was handled as radiologically contaminated waste and shipped to a licensed facility in Clive, Utah, for disposal.

*Source

_________________________________________________________________

Carborundum Company

State: New York

Location: Niagara Falls

Time Period: AWE 1943-1944; 1959-1967,; Residual Radiation 1945-1958; 1968-1992

Facility Type: Atomic Weapons Employer

Facility Description: In 1943 and 1944 the Carborundum Company at its Globar Plant and Buffalo Avenue locations was engaged in various phases of Manhattan Engineer District (MED) programs to determine suitable methods for engineering and shaping uranium rods. This work also involved the forming, coating, and canning of uranium rods for the MED pile. From 1959 through 1967, the company used powder fabrication techniques to manufacture uranium, plutonium, and carbide pellets for an AEC research program. The Hanford facility supplied Carborundum with materials during that period.

Carborundum also performed work during the 1950s that is not covered under EEOICPA, including fabricating nuclear fuel elements for commercial purposes and producing zirconium, hafnium, and titanium for AEC’s special reactor materials program.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under EEOICPA.

Listing:

Carborundum Company is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 03/15/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Carborundum Company is $5,918,552.

Carborundum Company Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim, and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

_________________________________________________________________

Crucible Steel Co.

State: New York

Location: Syracuse

Time Period: AWE 1951; Residual Radiation 1952-March 1, 2011

Facility Type: Atomic Weapons Employer

Facility Description: In 1951, New York Operations Office personnel performed a test forging and rolling of 10 thorium billets at Crucible Steel Company.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Crucible Steel Co. is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 03/22/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Crucible Steel Co. is $771,157.

Crucible Steel Co. Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

_________________________________________________________________

Electro Metallurgical

Also Known As: ElectroMet Corp., Umetco Minerals Corp., Union Carbide Corp., Electro-Metallurgical Corp.

State: New York

Location: Niagara Falls

Time Period: 1942-1953

Facility Type: Department of Energy

Facility Description: In 1942, the Electro Metallurgical Company (ElectroMet), a subsidiary of Union Carbide and Carbon Corporation, was contracted by the Manhattan Engineer District to design, engineer, construct, and operate a metal reduction plant.

Developing the technology to produce pure uranium metal was a priority for the Manhattan Project. ElectroMet received uranium tetrafluoride from Union Carbide’s Linde Air Products Division. ElectroMet reacted the uranium tetrafluoride with magnesium in induction furnaces to produce uranium metal. Once the metal was produced, it was cast into ingots, and the ingots were then shipped out for testing or for rolling. The leftover process residues were sent to other sites for uranium recovery, storage, or disposal. ElectroMet was also in charge of recasting metal, research and development in low- and high-grade uranium ores, and supplying calcium metal to Los Alamos and other laboratories.

From 1950 through 1953, the plant casted zirconium metal sponge into ingots. Ownership of the facility was transferred from the Atomic Energy Commission to ElectroMet in 1953.

Listing:

Electro Metallurgical is listed as a Department of Energy (DOE) site under the EEOICPA.

Classes:

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the Electro Metallurgical site in Niagara Falls, New York, from August 13, 1942 through December 31, 1947, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

(Note: This class was established from Petition 136)

History:

The Electro Metallurgical Company was located in Niagara Falls, NY in a building that is now part of the area occupied by Union Carbide Corporation. Uranium processing occurred in one building of the company (now Building 166 of Union Carbide). Uranium processing began in April, 1943 and continued until August 1946. Three shifts per day were run when the processing was at full operation. Production was shut down from August 1946 until October 1947, but resumed at that time until September 28, 1949 when production was stopped. The uranium processing carried out at the facility utilized uranium tetrafluoride and heat to cause a conversion to uranium metal.

Compensation:

As of 08/16/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Electro Metallurgical is $28,515,269.

Electro Metallurgical Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Function:

MED contract W-7405-Eng-14, initiated on November 14, 1942, called for design, engineering, construction, and operation of a plant to produce uranium metal from uranium tetrafluoride (UF4), also known as green salt. Expansion of the facility occurred under construction contracts W-7405-Eng-227 and 255. Electromet received UF4 from Union Carbide’s Linde Air Products Division plant at Tonawanda, New York,reacted it with magnesium in induction furnaces to convert it to uranium metal, and then recast the metal into 110- to 135-kilogram ingots. The products were generally shipped to either Hanford Engineer Works,Richland, Washington, Argonne National Laboratory, Argonne, Illinois, or Du Pont’s Chambers Works, Deepwater, New Jersey, for testing, or to Simonds Saw and Steel Company, Lockport, New York, Vulcan Crucible SteelCompany, Alliquippa, Pennsylvania, Revere Copper and Brass Company,Detroit, Michigan, or Joslyn Manufacturing and Supply Company, Fort Wayne, Indiana, for rolling. Process residues (dolomite slag, uranium chips, and crucible dross) were shipped to other sites for uraniumrecovery, storage, or disposal. These sites included Lake Ontario Ordnance Works (LOOW), Lewiston, New York, (now known as the DOE Niagara Falls Storage Site), Mallinckrodt Chemical Company, St. Louis, Missouri,Vitro Manufacturing Company, Canonsburg, Pennsylvania, the Du Pont Chambers Works, and Hooker Electrochemical Company, Niagara Falls, New York.

In addition to production of metal from green salt, Electromet recast scrap metal from Simonds, Chapman Valve Manufacturing Company, Indian Orchard, Massachusetts, and American Rolling Mill Company (location unknown). The contract also contained a provision for the conduct of research and development. Some work was done under this provision from April to October 1945. The exact nature of the work is not known, but it may have involved low- and/or high-grade uranium ores.

Production of uranium metal was suspended in August 1946 and resumed in October 1947. On November 30, 1948, Electromet was liquidated as a separate company and became the Electra Metallurgical Division of Union Carbide and Carbon Corporation. All rights, assets, liabilities, and contracts were transferred to Union Carbide. Production continued until September 28, 1949, when the last casting of uranium was conducted. The plant was placed in standby condition two days later.

Electromet also supplied calcium metal to Los Alamos Scientific Laboratory, Iowa State College, and AEC’s Santa Fe Yards under contracts W-26-021-Eng-13, AT (30-l)-Gen-137, 160, and.225, and AT-04-l-Gen-55, 56,57, 78, 91, and 101 (1945 to 1948). In April 1950, the UF4-to-metal plant was reactivated for casting zirconium metal sponge into ingots for the Naval Critical Requirement program. The work was conducted under W-7405-Eng-14 and funded under AEC contract AT(30-l)-861 with Titanium Alloy Manufacturing Division of National Lead Company (supplier of the zirconium). The plant was returned to standby condition at the completion of the work in September 1950. Portions of the facility were subsequently used under contract AT-(40-l)-1090 between Union Carbide and Carbon Research Laboratories, Inc. and AEC’s Oak Ridge Operations Office. This contract directed Union Carbide to conduct research and development on methods of forming metal that would minimize unnecessary machining, finishing, and waste. This work was conducted from January to June, 1951. Although the contract is not specific, the metal involved was probably uranium. Later, just prior to demolition, the building was also apparently used for titanium processing (contract number unknown). AEC involvement at the site ended when contract W-7405-Eng-14 expired on June 30, 1953.

Following termination of the MED/AEC contracts, Electromet processed uranium and thorium for commercial use under New York State radioactive material license 950-0139. From August 1965 through April 1972, Union Carbide Corporation produced 505 tons of slag bearing 9212 pounds of thorium dioxide and 1293 pounds of uranium oxide. This slag was placed in 55-gallon drums and buried in a designated area on plant property in a hole 20 feet deep with 4 to 5 feet of soil cover.

*Source

**

**Source

_________________________________________________________________

Hooker Electrochemical

Also Known As: Hooker Chemical Co., Occidental Chemical Corp., Occidental Chemical Corp., Specialty Chemical Div., Hooker Chemical and Plastics Corp.

State: New York

Location: Niagara Falls

Time Period: AWE 1943-1948; Residual Radiation 1949-1976

Facility Type: Atomic Weapons Employer

Facility Description: In January 1943, Hooker began work for the Manhattan Engineer District to manufacture fluoridated and chlorinated organic chemicals. The by-product of this work was hydrochloric acid that was subsequently used in the chemical processing of a uranium-bearing slag as a precursor of uranium recovery. This work was continued until shortly after World War II. Activities related to this contract ended June 1948. Hooker Electrochemical’s relationship with the AEC resumes between 1953 and 1958 as the Management and Operating Contractor for Plant 31 at the Lake Ontario Ordnance Works, listed separately in this database.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

NIOSH:

REVIEW OF THE NIOSH SITE PROFILE FOR THE HOOKER ELECTROCHEMICAL COMPANY

Listing:

Hooker Electrochemical is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Special Exposure Cohort (SEC) classes:

All Atomic Weapons Employees who worked at the Hooker Electrochemical Corporation in Niagara Falls, New York, during the operational period from July 1, 1944, through December 31, 1948, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees in the Special Exposure Cohort

Note: This class was established from Petition 141

Compensation:

As of 04/05/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Hooker Electrochemical is $3,211,485.

Hooker Electrochemical Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

Site Function:

In January 1943, Hooker Electrochemical Company began work under MED contract W-7405-Eng-28 to manufacture xylene hexafluoride(P-45), xylene hexachloride, and Miller’s fluorolubricant. The P-45 Program produced large amounts of hydrochloric acid. This byproduct was initially neutralized and discarded. A supplement (No. 3) was added to the contract that provided for use of the acid in the chemical processing (concentration) of uranium-bearing slag as a precursor to uranium recovery. The material to be processed included furnace liners from the nearby Electromet operation that were thought to contain enough uranium to warrant recovery. Wooden barrels carrying the material arrived by rail and were deposited on a concrete pad. The material was then transported by bucket conveyor to an area where it was screened. The large material was drummed and shipped without further processing, while the fines were treated with the acid to remove carbonates and oxides. After agitation the residues were filtered in a press to collect concentrated slag. The filtrate was disposed of in the sewer. The residues were then transferred into wooden barrels and shipped out by rail. This work continued until shortly after World War II.

Site Description:

The site is owned by Occidental Chemical Corporation, a subsidiary of Occidental Petroleum Corporation, and was known as Hooker Electrochemical Company at the time of the MED contract.

The site is located in an industrial area on the north bank of the Niagara River, approximately 2 miles east of Niagara Falls. All uranium operations were confined to the “D” area, 5.5 acres adjacent to the New York Central Railroad. Five buildings (D-5,6, 7, 8, and 9) were used in the MED program. However, except for the laboratory in building D-6 that was used for uranium analysis, all of the uranium handling was done largely outdoors in an area adjacent to the railroad siding location north of the MED buildings. A cinder block structure was constructed to house the major process equipment,which included four wood tanks with agitation equipment, a filter press, and a bucket elevator and conveying system. When the P-45 Program ended, the five buildings were outfitted for new processes. The structure and equipment used for the uranium operations (including the concrete pad) was removed (disposition unknown) to make room for process expansion. Building 5 was destroyed by a process explosion during the late 1950s. The other four buildings were still in use at the time of the 1976 survey, but all have since been razed except for a small portion of building 6, which is being used as a storage shed.

*Source

_________________________________________________________________

Ithaca Gun Co.

Also Known As: Ithaca Gun Club

State: New York

Location: Ithaca

Time Period: 1961-1962

Facility Type: Atomic Weapons Employer

Facility Description: During 1961-1962, Ithaca Gun conducted tests involving the forging of hollow uranium billets into tubes for the metallurgical group at National Lead Company of Ohio (Fernald).

Listing:

Ithaca Gun Co. is listed as an Atomic Weapons Employer under the EEOICPA.

Compensation:

As of 04/12/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Ithaca Gun Co. is $150,450.

Ithaca Gun Co. Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*INTRODUCTION AND SITE HISTORY:

In 1961 and 1962, the Ithaca Gun Company (IGC) was subcontracted by National Lead of Ohio (NLO) to conduct tests involving the forging of hollow uranium billets into tubes for the Atomic Energy Commission (AEC), predecessor agency of the U. S. Department of Energy (DOE). A series of tests were performed in 1961 to determine the abilities of the Gun Forging Machine’s vertical forging unit, used by IGC in the manufacturing of shotgun barrels, to forge hollow uranium billets into tubes for possible use as fuel cores. Additional tests to investigate alternative methods of producing fuel cores were conducted at IGC in 1962. The forging process involved heating the uranium billet to extreme temperatures, followed by mechanical hammering and rapid cooling in quench drums. The process created residual contamination in the form of metal tilings and dust. Because of the potential for contamination of equipment and surrounding surfaces, all testing was conducted in an enclosed, secluded building of the plant.

According to information obtained from NLO justification and trip reports, approximately 164 uranium feed stock tubes were used during the period of testing (Workhum 1961; Jansen and Nuckels 1962). NLO controlled most aspects of the work including handling, transporting, and accountability of the uranium and process waste, health and safety, and post-test decontamination efforts. IGC supplied all of the equipment, equipment operators, and special tooling required for the forging process. The site records indicate that NLO exercised considerable effort to minimize contamination during the testing process. Records also indicate that monitoring of equipment, exhaust from dust collectors, and outdoor paved areas was performed routinely and decontamination performed immediately if uranium contamination was detected.

Upon completion of the project in 1962, all uranium shapes, uranium-bearing dust, and contaminated liquid and sludge were returned to NLO. The entire area, including the exteriorpavement and grounds adjacent to the testing area, were monitored and only background levels remained after cleanup. However, records do not specify cleanup criteria or guidelines. Due to this uncertainty, further radiological evaluation was needed to determine whether residual uranium contamination was present in excess of DOE guidelines.

DOE reviewed available historical documentation describing the previous AEC activities conducted at the Ithaca Gun Company site and based on the results, requested that the Environmental Survey and Site Assessment Program (ESSAP) of the Oak Ridge Institute for Science and Education (ORISE) perform a radiological survey of the area used for the uranium forging tests. The purpose of the survey was to determine if residual uranium contamination was present on the property for which DOE has authority to require remedial action under the Formerly Utilized Sites Remedial Action Program (FUSRAP). FUSRAP was created in 1974 to identify, investigate, and cleanup or control sites where contamination above today’s guidelines remains from the early years of the Nation’s atomic energy program.

SITE DESCRIPTION:

The former Ithaca Gun Company facility is located at 123 Lake Street in Ithaca, New York, approximately 1.6 kilometers (1 mile) east of state highway 13 (Figure 1). The facility had ceased operations in the late 1980’s and is currently unoccupied. A cyclone fence encloses the site. The present owner of the property is State Street Associates L.P.

The building that formerly housed the forging machine used for the uranium tests is located at the north end of the site (Figure 2). The building is constructed with concrete block walls, a sloped wooden roof, and a concrete slab floor. The building dimensions are approximately 18 meters by 11 meters (Figure 3). Exterior areas of the building include concrete drives bordering the north, east, and west, and another building is attached on the southern end of the Gun Forging Machine Building. Drainage from this area of the site flows north and northwest to where the land drops off sharply to a ravine that contains a creek at the base.

*Source

_________________________________________________________________

Lake Ontario Ordnance Works

Also Known As: LOOW, Niagara Falls Storage Site (NFSS), Niagara Falls Vicinity Properties

State: New York

Location: Niagara Falls

Time Period: 1944-1997

Facility Type: Department of Energy

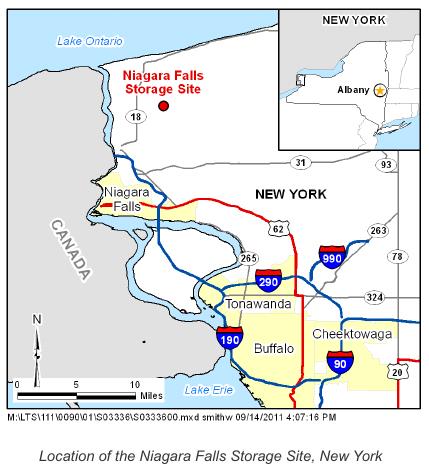

Facility Description: In 1944, the Manhattan Engineer District (MED) obtained a portion of the Lake Ontario Ordnance Works (LOOW) from the Department of Defense (DOD) for storage of low-grade radioactive residues resulting from pitchblende ore processing at the Linde Air Products facility. In 1948, when the DOD decommissioned the LOOW, the AEC acquired 1511 acres of the site, including the original storage areas. The AEC declared most of this property as excess in 1955, and by 1968 the General Services Administration was able to dispose of 1298 acres, with 213 acres remaining under AEC control. In 1975, additional property was transferred to the town of Lewiston, leaving the present 191-acre site. The DOE portion of the site became known as the Niagara Falls Storage Site (NFSS). The site remained under DOE control until 1997 when it was transferred to the Corps of Engineers under the FUSRAP program.

Following World War II, Linde’s refinery was decommissioned and contaminated equipment was disposed at the LOOW. Contaminated materials from other MED/AEC facilities were also shipped to LOOW for disposal. Beginning in 1949, residues from operations at the Mallinckrodt Chemical Works were shipped to LOOW for storage. During the early 1950’s, the AEC portion of the LOOW was also used for interim storage of uranium and thorium billets and rods being processed by various New York companies.

During 1953-1954, the AEC constructed a boron isotope separation plant at the LOOW, which began operations in 1954. The operating contractor for this plant was the Hooker Electrochemical Company which referred to it as Plant 31 (P-31).. In 1958, the facility was placed on stand-by and a maintenance contractor, Page Airways, was employed for routine surveillance. The operation was restarted in 1964, with Nuclear Materials and Equipment Company as the operating contractor. In 1971, the boron facility was again placed on stand-by with National Lead Company of Ohio (NLO) as the caretaker. In 1981, Bechtel National took over the caretaker contract and began plans for remedial work at the site. Clean-up began in 1982.

CONTRACTORS: Hooker Electrochemical (1953-1958); Page Airways (1958-1964); Nuclear Materials and Equipment Company (NUMEC) (1964- 1971); National Lead Company of Ohio (1971-1981); Bechtel National (1981-1997)

Listing:

Lake Ontario Ordnance Works is listed as a Department of Energy (DOE) site under the EEOICPA.

DOE Contractor:

DOE contractors associated with this class include Hooker Electrochemical, Page Airways, Nuclear Materials and Equipment Co., National Lead Company of Ohio, and Bechtel National.

Classes:

All employees of the DOE, its predecessor agencies, and their contractors and subcontractors who worked at Lake Ontario Ordnance Works in Niagara Falls, New York from January 1, 1944 through December 31, 1953, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees in the SEC.

Compensation:

As of 08/16/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Lake Ontario Ordnance Works is $4,139,945.

Lake Ontario Ordnance Works Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Description and History:

The Niagara Falls Storage Site, New York, is a 191-acre site located on Pletcher Road in the towns of Lewiston and Porter, Niagara County, in northwestern New York. It is approximately 10 miles north of the city of Niagara Falls and 19 miles northwest of Buffalo, New York. The site is a remnant of the U.S. Army’s 7,500-acre Lake Ontario Ordnance Works. The property includes a 10-acre interim waste containment structure (IWCS) for radioactive waste and residues, which is covered by an interim cap designed to retard radon emissions and rainwater infiltration, and three buildings: Building 401, which contains isolated areas of fixed, low-level radioactive contamination, and two maintenance buildings.

In 1944, during World War II, the Manhattan Engineer District (MED) used the site for the storage and transshipment of radioactive residues and wastes from the processing of uranium ore. By 1948, the War Assets Administration had transferred or sold 6,000 acres of the original property, and the remaining 1,500 acres were subsequently given to the newly formed Atomic Energy Commission (AEC). From 1955 to 1975, more than 1,300 acres were transferred or sold to private concerns, leaving the current 191 acres that are owned by the U.S. Department of Energy (DOE).

In 1943, Building 401 was used as the powerhouse for the trinitrotoluene (TNT) plant at the Lake Ontario Ordnance Works; operations involving the manufacture of TNT only continued for 1 year. The building was used to manufacture boron-10, which is not radioactive, from 1953 to 1959 and from 1965 to 1971.

In 1952, drums containing radioactive uranium ore processing residues (K-65) were stored in a silo, which has since been demolished. In the 1980s, DOE placed the residues in the engineered IWCS, which was completed in 1991. DOE began cleanup of the radioactive wastes in 1982 under the Formerly Utilized Sites Remedial Action Program (FUSRAP), and as of March 2004, DOE and USACE had consolidated approximately 235,000 cubic yards of contaminated material and 25,000 cubic yards of radioactive residues (of which approximately 4,000 cubic yards comprise K-65 high activity residues) into the IWCS. Although radiological contamination of soil exists throughout the site, it is at levels considerably below those of the materials stored in the IWCS. The primary contaminants of concern at the site are radium, thorium, and smaller amounts of uranium.

**Source

**Source

_________________________________________________________________

Linde Air Products

Also Known As: Linde Air Products Div. Of Union Carbide Corp. , Linde , Linde Center , Chandler Plant , Chandler Street Plant, Linde Chandler Plant

State: New York

Location: Buffalo

Time Period: 1945-1947

Facility Type: Atomic Weapons Employer

Facility Description: The Linde Air Products facility, also known as the Chandler Plant, was involved in the development and production of barrier for the Oak Ridge Diffusion Plant. During World War II, Linde was part of the Carbide and Carbon Chemical Corporation, later known as Union Carbide.

Listing:

Linde Air Products is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 04/19/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Linde Air Products is $2,746,819.

Linde Air Products Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Function:

The Linde Air Products Division of Union Carbide operated a plant in Tonawanda, New York, for the Manhattan Engineer District (MED) and the Atomic Energy Commission (AEC) from 1942 through approximately 1948. The facility was known as the Ceramics Plant. Uranium production and some nickel processing were conducted at the site under several contracts;including W-7401-Eng-14. During the first 3 years, pitchblende ore from,the Belgian Congo and concentrates from Colorado Plateau ore were converted to black oxide (U3O8,). Residues from the pitchblende processing were stored at a portion of the former Lake Ontario Ordnance Works, now known as the Department of Energy (DOE) Niagara Falls Storage Site. The refinery residues from the domestic ore were moved to the nearby Haist property (now wastes for the refinery owned by Ashland Oil Company). Some liquid operation were disposed of in sanitary sewers, storm sewers, and in shallow on-site wells. The facility also contained a process that converted black oxide into uranium oxide (UO2). It operated at the Ceramics Plant for about 1 year. A separate building (No. 38) housed a third process for converting the uranium,oxide to “green salt” (uranium tetrafluoride UF4). This process was used in conjunction with the Electromet Niagara Falls operation during World War II and for the following 2 years. At the second facility (known as the Chandler Street Buffalo), Linde developed and produced non-radioactive the Oak Ridge Gaseous Diffusion Plant under contract W-26-121-Eng-46. Other contracts have been identified, but the exact nature of the work involved is unknown: W-7401-Eng-15 (black oxide, October 17, 1942), W-17-028-Eng-29 (ore concentrate, March 4, 1945), and AT(JO-I)-GEN-165 (type of material and date unknown).

Site Description:

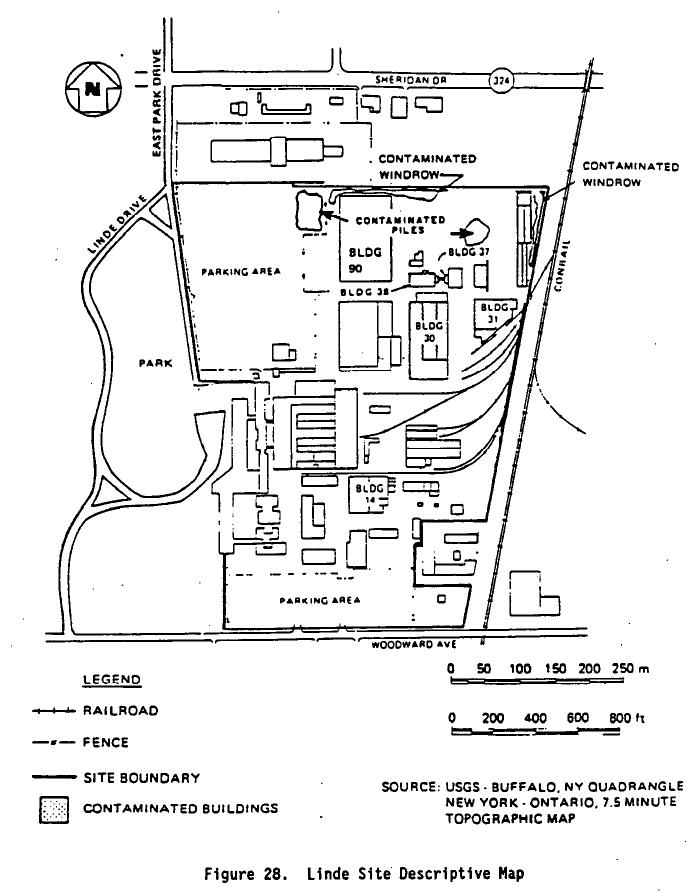

The Linde Division property in Tonawanda where the ceramics plant was located is bordered on the north and east by other industries; on the south by small businesses, industries, and undeveloped land; and on the west by a golf course. Five buildings (Buildings 14, 30,31, 37, and 38) were involved in the uranium separation and conversion process (Figure 28). Building 14 (now fabrication facilities, offices, and storage area) was used for small-scaledevelopment of the separation process. Black oxide conversion touranium dioxide was carried out in Building 30 (now a shipping and receiving warehouse). The product from Building 30 was then transferred to Building 38 (currently a warehouse) where fluorination resulted in an end product of uranium tetrafluoride. Buildings 31 and 37 were also used in these operations. Building 37 is not being used currently.

Owner History:

This facility is owned by the Linde Air Products Division of the Union Carbide Corporation. Union Carbide constructed Building 14 in the mid-1930’s. MED constructed four buildings (30, 31, 37, and 38) on land owned by Union Carbide. The buildings were transferred to Linde upon termination of the AEC contract.

*Source

_________________________________________________________________

Linde Ceramics Plant

Also Known As: Tonawanda Laboratory (AWE portion of the plant), Linde Air, Praxair

State: New York

Location: Tonawanda

Time Period: AWE/DOE* 1942-1953; Res. Rad. 1954-1987; 1993-1995; 1997-March 1, 2011;

DOE 1988-1992; 1996 (remediation)

Facility Type: Atomic Weapons Employer Department of Energy

Facility Description: The Linde Air Company performed uranium and nickel processing for the Manhattan Engineer District (MED) and the Atomic Energy Commission (AEC) at the Ceramics Plant in Tonawanda. African and Canadian ores were milled to black oxides at the plant. Documents indicate that the facility was placed on standby as of March 1, 1950. Linde’s contractual agreements with the AEC continued through 1953 for various activities relating to closing out work at the Tonawanda location. Linde was a part of Carbide and Carbon Chemical Corporation (C&CCC), which then became Union Carbide.

In 1980, Linde Ceramics was designated as part of the Formerly Utilized Site Remediation Action Program (FUSRAP) and work under this program was performed during 1988-1992, and then again in 1996. The 1996 work was performed under the Bechtel National Inc. umbrella contract for DOE environmental site remediation.

*Buildings 30,31,37 and 38 of the Linde Ceramics Plant meet the definition of a DOE facility for the years 1942 through 1953. This means that employees who worked in these buildings during these years are eligible under both Part B and E of the EEOICPA.

The Tonawanda Laboratory, which is also known as Building 14, meets the definition of an AWE for the years 1942-1953. Under the EEOICPA, employees of AWE facilities are not eligible under Part E of the EEOICPA.

Listing:

Linde Ceramics Plant is listed as an Atomic Weapons Employer (AWE) site from 1942-87, 1993-95, and 1997-2009, and as a Department of Energy (DOE) site from 1988-92 and 1996.

Classes:

Atomic weapons employees who worked at the Linde Ceramic Plant from October 1, 1942, through October 31, 1947, and who were employed for a number of work days aggregating at least 250 work days, either solely under this employment or in combination with work days of employment occurring within the parameters (excluding aggregate work day requirements) established for other classes of employees included in the SEC

All Atomic Weapons Employees who worked at the Linde Ceramics Plant in Tonawanda, New York, from January 1, 1954 through December 31, 1969, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees in the SEC.

All Atomic Weapons Employees who worked in any area at the Linde Ceramics Plant in Tonawanda, New York, from November 1, 1947, through December 31, 1953, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the SEC.

Compensation:

As of 08/16/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Linde Ceramics Plant is $52,309,458.

Linde Ceramics Plant Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

NIOSH site profile:

SPECIAL EXPOSURE COHORT PETITION INFORMATION FOR LINDE

October 1, 1942, through October 31, 1947

NIOSH has determined, and the Secretary of the U.S. Department of Health and Human Services

(DHHS) has concurred, that it is not feasible to reconstruct internal radiation dose for (Leavitt 2005):

Atomic Weapons Employees who worked at the Linde Ceramics Plant from October 1,

1942, through October 31, 1947, and who were employed for a number of work days

aggregating at least 250 work days either solely under this employment or in

combination with work days occurring within the parameters (excluding aggregate work

day requirements) established for other classes of employees included in the SEC

[Special Exposure Cohort].

Subsequent correspondence (Elliott 2006) confirmed that the Tonawanda Laboratory (as well as all

other buildings on the Linde site) are included in this SEC class designation. Reconstruction of

external exposure (including medical X-ray examinations) has been determined to be feasible (Leavitt

2005).

For any claim referred to NIOSH regarding an employee,

•who was employed during the SEC class period but because of limited employment during this

period is not a member of the SEC, or

•who is a member of the SEC class and whose cancer is not defined as a specified cancer under

EEOICPA (and so is not eligible for compensation under EEOICPA without a dose reconstruction),

NIOSH will continue to attempt to complete a dose reconstruction for the exposure period based

solely on external and medical X-ray radiation sources. However, because of the SEC class

determination that it is infeasible to adequately reconstruct internal dose during the period from

October 1, 1942, through October 31, 1947 (Leavitt 2005), dose estimates for this period are

considered partial dose estimates.

January 1, 1954, through December 31, 1969

NIOSH has determined, with concurrence from the Secretary of DHHS (Sebelius 2011), that internal

doses at the Linde Ceramic Plant cannot be reconstructed with sufficient accuracy from the beginning

of 1954 through the end of 1969. For this reason, the following class of Linde employees has been

added to the SEC (Sebelius 2011):

All Atomic Weapons Employees who worked at the Linde Ceramics Plant in

Tonawanda, New York, from January 1, 1954, through December 31, 1969, for a

number of work days aggregating at least 250 work days, occurring either solely under

this employment, or in combination with work days within the parameters established

for one or more other classes of employees in the Special Exposure Cohort.

This SEC class includes all workers during the SEC class period. Because of the identified dose

reconstruction infeasibility, all dose reconstructions for all workers having employment during the SEC

class period are considered partial dose reconstructions. If monitoring data are available for workers

included in the SEC class, dose is to be assigned as appropriate based on such data; however, such

dose reconstructions are still considered partial dose reconstructions because NIOSH has determined

that internal exposures during the SEC class period cannot be bounded.

SITE DESCRIPTION AND OPERATIONAL HISTORY

When the U.S. government and its contractors first became interested in uranium, LAPC, then a

division of Union Carbide and Carbon Corporation, operated Tonawanda Laboratory, which had been

producingU3O8 that was sold as a coloring agent for ceramics. Because of the great interest in obtaining uranium that could be used to create experimental uranium piles, Linde was contracted to develop uranium chemical processes and build a facility that could process large amounts of uranium ore. This commissioned facility was called the Linde Ceramics Plant. The plant worked with two types of radioactive material:

• Refined uranium materials and preprocessed (partially refined) domestic ores, and

• Unprocessed African ores.

Processing of the African ores involved exposures to significantly higher levels of 230Th, 226Ra, and

222Rn. In the other materials, the initial refining process probably removed most nonuranium

radionuclides. Due to the long half-lives of 230Th and 231Pa, significant ingrowth of these nuclides and their progeny in the 238U and 235U decay chains did not occur in the interval between the refining of the materials and their processing at Linde.

LAPC performed work for the Manhattan Engineer District (MED) and its successor the U.S. Atomic

Energy Commission (AEC) between 1942 and 1949. Tonawanda Laboratory performed research and

development (R&D) on uranium processing for the MED beginning in late 1942 and probably ending in 1946. In the early years, it operated pilot plants to develop procedures for the Ceramics Plant. The Ceramics Plant produced uranium materials for the MED and AEC from 1943 to 1946 and from 1947 to 1949. From 1947 to 1949 (and perhaps earlier), Linde received UO2 for processing from Mallinckrodt Chemical Works (AEC 1949a). The plant also produced nickel material for the K-25 diffusion barrier. The Ceramics Plant was in standby from mid-1946 to late 1947. The end of production in 1949 was followed by cleanup and decontamination and then turnover of the production facilities back to Linde. This turnover probably occurred in 1954.

Uranium processing at the Ceramics Plant involved three steps:

• Step I, conversion of ore to U3O8 (black oxide);

• Step II, conversion of U3O8 to UO3 (orange oxide) as an intermediary product and then to UO2

(brown oxide);

• Step III, conversion of UO2 to UF4 (green salt).

The following sections provide more detailed histories of Linde facilities, radiation sources, and processes that related to MED/AEC radiation exposures. Key dates are noted in Table 2-1.

FACILITIES

The Linde Ceramics Plant and Tonawanda Laboratory were on land that was owned by Union

Carbide at East Park Drive and Woodward Avenue in Tonawanda, New York (ORNL 1978, Fig. 3).

The site is near the intersection of Riverview Boulevard and Woodward Avenue. It is north of

Woodward Avenue, east of East Park Drive, and west of the Conrail railroad tracks.

Tonawanda site buildings that were involved in MED/AEC work are shown in Figure 2-1. The

Tonawanda Laboratory occupied Building 14, and the Ceramics Plant used Buildings 30, 31, 37, 38,

and A. Building B contained MED offices. Ownership of the Ceramics Plant buildings was transferred

to LAPC after the site cleanup that began with the shutdown of production in 1949. The transfer

probably was completed in 1954. In the 1990s, the site was acquired by Praxair (USACE 2003).

Buildings A and B

Building A was the Linde Ceramics Plant office building for administrative and support personnel.

During the MED years, Building B housed the Tonawanda Area Engineer office of the MED (Dupree

1983a) and probably was later used by AEC personnel. The designations A and B were adopted for

this document and might be different from the official Linde or MED designations. Buildings A and B

were no longer standing in 1978, when the results of a 1976 radiological survey were issued by Oak

Ridge National Laboratory (ORNL 1978).

Figure 2-1 is based on Figures 3-1 and B-11 of BNI (1982), Figure 3 of Frame et al. (1981), and LAPC

(1945a).

A shelter in which workers were allowed to smoke was at the south end of Building B (Dupree 1983a).

This was probably for use only by office workers. A separate smoking shelter was provided for

production workers (Klevin 1949a, data sheets 543 and 546).

Table 2-1. Key dates.

| Assumed date or period a |

Event or activity |

| Ceramics Plant 06/01/1943–07/31/1946 b | Step I production (U3O8 from ore or sludge) |

| 06/01/1943–11/30/1943 | Preprocessed ores (domestic and scrap) |

| 12/01/1943–11/12/1944 | African ores |

| 11/13/1944–01/31/1946 | Preprocessed domestic ores |

| 02/01/1946–02/28/1946 | African ores (48%) and preprocessed domestic ores (52%) |

| 03/01/1946–06/30/1946 | African ores |

| 07/01/1946–07/31/194604/27/1943–03/08/1944 c07/25/1943–06/26/1946 d | African ores and preprocessed ash Step II production (UO2 from U3O8)Step III production (UF4 from UO2) |

| 08/01/1946–09/14/194709/15/1947–10/31/1947 e11/01/1947–06/30/1949 f10/01/1944–02/28/1946 g07/01/1949–03/31/1950 h07/01/1949–12/31/1954 i | Stand by Step III rehabilitation Step III productionProduction of nickel material for K-25 diffusion barrierCleanup of Building 30Cleanup of Linde Ceramics Buildings |

| Before 1978 | Demolition of Buildings A and B (office buildings on Figure 2-1) |

| After 195408/31/1981 j08/31/1996 j09/05/1998 k09/30/2000 l | Postcleanup period Demolition of Building 37 began Demolition of Building 38 began Demolition of Building 30 beganSoil remediation began (scheduled for completion in 2007) |

| Tonawanda Laboratory 10/01/1942–07/31/1946 l08/01/1946–12/31/1946 m | MED-related R&D operations Cleanup period |

| Assumed date or period | Event or activity |

| After 1947 | Postcleanup period |

| 04/30/2004 j | Demolition of Building 14 began |

a. Unless more precise information was available, activities were assumed to begin on the first day of the start

month and to end on the last day of the completion month in the data source, and demolition activities were

assumed to begin on the last day of the start month in the data source.

b. All Step I dates and data are based on Table B-1 of Wallo, Vierzba, and Roberts (1981) except for the

November 1944 transition date from African to domestic ore. The date was determined from analysis of Step I

film badge data (see Section 4.1.3.2).

c. LAPC (1946a, p. 40).

d. LAPC (1946b, p. 42).

e. Start date based on Kent (1947, p. 1).

f. Start date based on Rennich (1947). End date based on Heatherton (1948a).

g. Hickey, Crawford-Brown, and Tankersley (1988, Figure 13, p. 2).

h. Start date assumed to be day after end of Step III production; end date estimated based on Eisenbud (1950).

i. Start date assumed to be day after end of Step III production; end date estimated based on Harris (1954).

j. Pilon (2004).

k. USACE (1998).

l. Start date based on Jenness and Ewing (1943). End date assumed to be the end date of 1943 to 1946

production at the Ceramics Plant.

m. Start date based on estimated end date of R&D period; end date estimated.

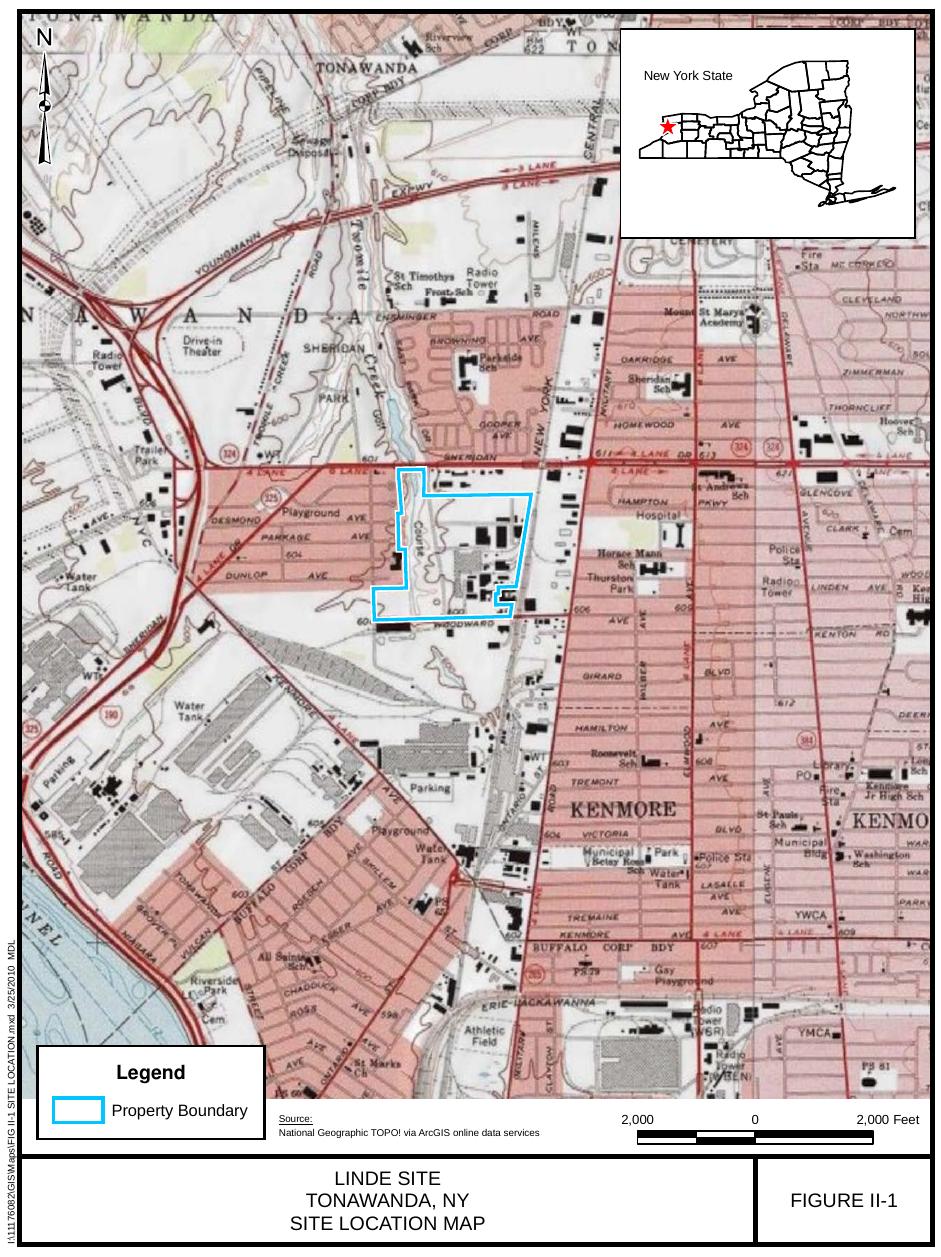

*Site Characteristics and Uses:

The Linde Site comprises about 135 acres located at 175 East Park Drive (off Sheridan Drive) in the Town of Tonawanda, New York. The Site Location Map is illustrated in Figure II-1. The Linde Site is bounded on the north and south by other industrial properties and small businesses, on the east by CSX Corporation (CSX) railroad tracks and National Grid property and easements, and on the west by a park owned by Praxair, Inc. A low-density residential area and an elementary school lie west of the park. The Site Plan is illustrated in Figure III-1, an aerial photograph of the Linde Site taken in April 2009.

The property contains office buildings, fabrication facilities, warehouse storage areas, material laydown areas, and parking lots with access to the property controlled by Praxair, Inc. The property is underlain by a series of utility tunnels that interconnect some of the main buildings and by an extensive network of storm and sanitary sewers. Public water and sanitary sewer services are provided to the property. The cleanup criteria proposed by USACE was developed toprovide for an acceptable level of protection in accordance with CERCLA and was based on an industrial exposure scenario, which is the most likely future land use.

Land uses in close proximity to the property include the CSX property, commercial and residential areas, and Kenmore Sisters of Mercy Hospital to the east; small businesses, light industries, and residential areas to the north; business and industrial areas to the south; and a low-density residential area and Holmes Elementary School to the west. Sheridan Park, owned by the Town of Tonawanda’s Parks and Recreation Department, is located a quarter mile to the northwest of the property. Two Mile Creek flows through this property.

Recreational uses near the property include an 18-hole public golf course, picnicking, and playgrounds. Sensitive uses within one mile of the Linde property include five schools, two community buildings, and a senior citizens’ center. The Linde property is fenced and has a buffer zone of grass and trees around the main buildings.

Site History and Contaminants:

During the early to mid-1940s, portions of the property formerly owned by Linde Air Products Corp., a subsidiary of Union Carbide Industrial Gas, now owned by Praxair, Inc., were used for the separation of uranium ores. These processing activities, conducted under MED contracts, resulted in radioactive contamination of portions of the property and buildings. A radiological survey report prepared for the Linde Site by Oak Ridge National Laboratory (ORNL) in 1978 reported that uranium dioxide was separated from uranium ores and uranium dioxide was converted to uranium tetrafluoride at the site between 1940 and 1948. The 1978 ORNL report also stated that the Linde Air Products Division was under contract to MED to perform uranium separations from 1940 through approximately 1948.

As described in the RI report for the Tonawanda Sites (DOE 1993), five (5) Linde buildings were involved in MED activities: Building 14 (built by Union Carbide in the mid-1930s) and Buildings 30, 31, 37, and 38 (built by MED on land owned by Union Carbide). Ownership of Buildings 30, 31, 37, and 38 was transferred to Linde when the MED contract was terminated. As discussed in the RI report, there were three phases to the processing conducted at the Linde Site as follows:

• Phase 1: uranium separation from the ore, which consisted of separating triuranium octoxide (U3O8) from the feedstock materials by a series of process steps consisting of acid digestion, precipitation, and filtration.

• Phase 2: conversion of U3O8 to uranium dioxide

• Phase 3: conversion of uranium dioxide to uranium tetrafluoride

The RI report states that the contaminants of concern at the Linde Site were primarily associated with the waste streams and residues of the Phase 1 operation and that any residues from the Phase 2 and 3 operations were reprocessed. The primary activity was the separation of uranium from the ore, and the principal contaminants of concern (COCs) were from the processing of wastes and residues from Phase I processing.

Under the MED contract, uranium ores from seven different sources were processed at Linde: four African ores (three low-grade pitchblendes and torbernite) and three domestic ores (carnotite from Colorado). The domestic ore tailings sent to Linde resulted from commercial processing, conducted primarily in the Western United States, to remove vanadium. The vanadium removal process resulted in disruption of the uranium decay chain and the removal of radium. For this reason, uranium supplied to Linde had low concentrations of radium compared with the natural uranium (U) and thorium-230 (Th-230) concentrations.

The African ores shipped to Linde as unprocessed mining ores contained uranium in equilibrium with all of the daughter products in its decay chain (e.g., Th-230 and radium-226 [Ra-226]). The other constituents of the ores were similar to those of the domestic ores. From mid-1943 to mid-1946, approximately 28,000 tons of ore was processed at the Linde Site.

The principal solid waste resulting from Phase 1 processing was a solid, gelatinous filter cake consisting of impurities remaining after filtration of the uranium carbonate solutions. Phase 1 processing also produced insoluble precipitates of the dissolved constituents, which were combined with the tailings. The precipitated species included large quantities of silicon dioxide, iron hydroxide, calcium hydroxide, calcium carbonate, aluminum hydroxide, lead sulfate, lead vanadate, barium sulfate, barium carbonate, magnesium hydroxide, magnesium carbonate, and iron complexes of vanadium and phosphorus. COCs that impacted soils and buildings and posed an unacceptable risk to human health and the environment under an industrial scenario (including construction and utility workers) were identified as radium, thorium, and uranium, specifically:

• Ra-226

• Th-230

• Total uranium (Utotal )

_________________________________________________________________

Seaway Industrial Park

Also Known As: Charles St. Plant

State: New York

Location: Tonawanda

Time Period: AWE 1974 ; Residual Radiation 1975-March 1, 2011

Facility Type: Atomic Weapons Employer

Facility Description: In 1974, the Ashland Oil Company constructed bermed areas on the Ashland #1 property to hold two petroleum tanks. Some of the soil removed during construction was disposed of in three areas of the Seaway Industrial Park landfill. Subsequent investigations determined that the soil from the Ashland site contained radioactive contaminants exceeding Department of Energy (DOE) guidelines. This soil came from an area used for disposal of radioactive residues from the nearby Linde Air Products site. This company processed uranium for the Atomic Energy Commission and the Manhattan Engineer District, predecessor agencies of the Department of Energy (DOE).

Although the Seaway Industrial Park was designated as part of the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1984, no work under this program was performed prior to its transfer to the Army Corps of Engineers.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Seaway Industrial Park is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Compensation:

As of 05/17/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Seaway Industrial Park is $0.

Seaway Industrial Park Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

_________________________________________________________________

Simonds Saw And Steel Co.

Also Known As: Simonds Saw and Steel Div., Guterl Special Steel Corp., Guterl Steel Facility, Guterl Steel Corporation, Allegheny-Ludlum Steel Corp., Simonds Steel Division, Wallace-Murray Corporation

State: New York

Location: Lockport

Time Period: AWE 1948-1957; Residual Radiation 1958-March 1, 2011

Facility Type: Atomic Weapons Employer

Facility Description: Simonds Saw and Steel rolled uranium billets into rods for the AEC as part of the multi-site process overseen by the New York Operations Office for the production of uranium metal for fabrication into slugs for fueling Hanford production reactors. Simonds also rolled thorium metal whose most likely use was irradiation in Hanford reactors for the weapons program. Simonds rolled between 25 million and 35 million pounds of uranium and between 30,000 to 40,000 pounds of thorium.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Simonds Saw And Steel Co. is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Classes:

All Atomic Weapons Employer employees who worked at Simonds Saw and Steel Co. from January 1, 1948 through December 31, 1957, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

Petitions Qualified for Evaluation:

Location: Lockport, New York

Job Titles and/or Job Duties: All employees who worked in any area during the applicable covered thorium operational and residual periods.

Period of Employment: January 1, 1951 through December 31, 2006

Compensation:

As of 05/10/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Simonds Saw and Steel Co. is $18,942,594.

Simonds Saw and Steel Co. Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

* SITE HISTORY:

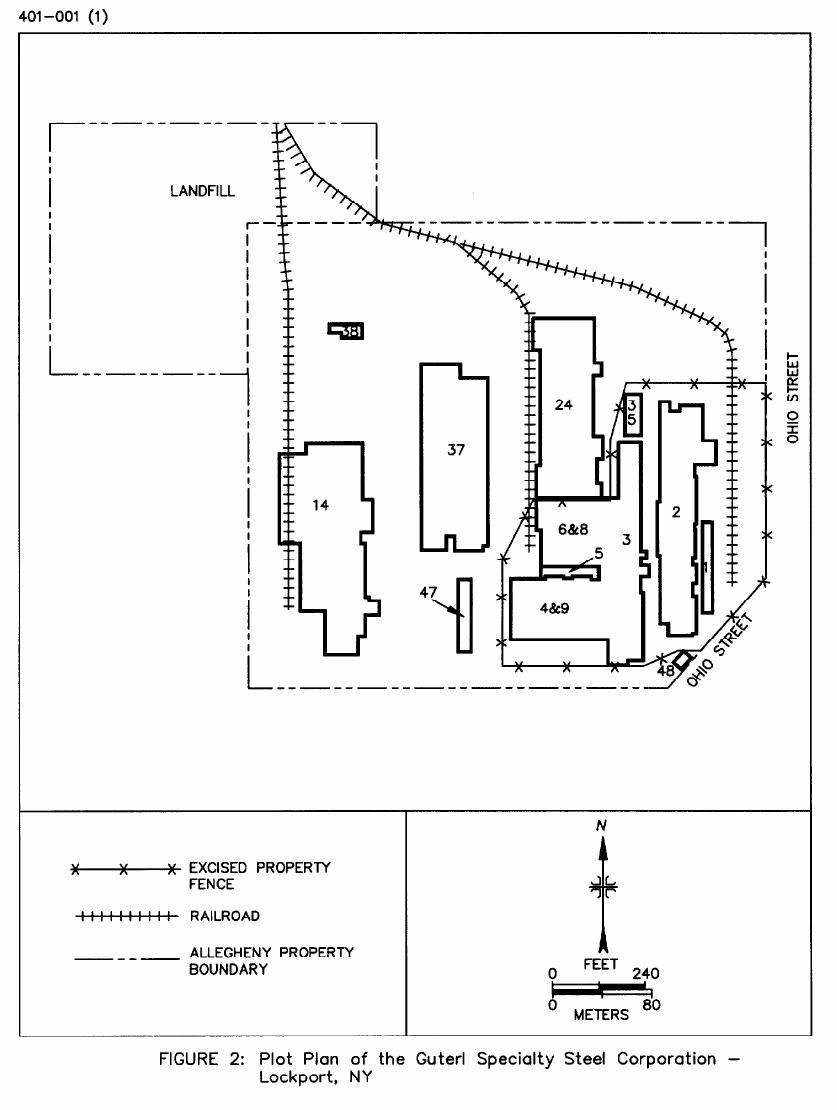

The Guterl Specialty Steel Corporation (GSSC) site, formerly known as the Simonds Saw and Steel Company, performed rolling mill operations on uranium metal, and to a much smaller extent, thorium metal, during the period from 1948 to 1956. Uranium and thorium operations were performed under two separate contracts. The first contract, AT-30-l-Gen-339, initiated in May of 1948 and in effect until 1952, was negotiated with the New York Operations Office of the Atomic Energy Commission (AEC), predecessor to the U.S. Department of Energy (DOE). The second contract, number S-4, was a subcontract from the AEC with National Lead of Ohio (NLO), which extended the plant activities until 1956. In total, between 25 and 35 million pounds of uranium and approximately 30 to 40 thousand pounds of thorium were rolled from 1948 until operations discontinued in 1956. More than 99 percent of the work done under these contracts involved uranium, which was rolled on the 16-inch rolling mill located in Building 8. Several small lots of uranium bars were run through the 10-inch rolling mill, and approximately 15 to 20 ingots were processed in the hammer forge shop, which was located in Building 3 (NYDEC 1994a and b).