The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Clarksville Modification Center is covered for compensation under the EEOICPA. Clarksville Modification Center EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Clarksville Modification Center

Also Known As: Mason & Hanger – Clarksville Base

State: Tennessee

Location: Clarksville

Time Period: 1949-1967

Facility Type: Department of Energy

Facility Description: The Clarksville Modification Center was established in 1958 for the purpose of testing and modifying the components of nuclear weapons. The Center was located near Clarksville, TN, on a corner of the Ft. Campbell, KY, military reservation. Prior to 1958 some buildings were used by the AEC for storage. The Clarksville Modification Center was closed in September 1965 and its functions were transferred to Pantex and Burlington. In 1967 the AEC surrendered control of the area back to the Army.

Throughout the course of its operations, the potential for beryllium exposure existed at this site.

CONTRACTOR: Mason & Hanger-Silas Mason (1958-1965); Sandia Corporation was the storage contractor (1949-1967)

Listing:

Clarksville Modification Center is listed as a Department of Energy (DOE) site under the EEOICPA.

Special Exposure Cohort (SEC) Classes:

The SEC classes for Clarksville Modification Center include all employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the Clarksville Modification Center, Fort Campbell, in Clarksville, Tennessee, from August 1, 1949, through December 31, 1967, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

(Note: This class was established from Petition 202)

Compensation:

As of 01/11/2023, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Clarksville Modification Center is $14,537,513. Click here for a current accounting of compensation paid to former Clarksville Modification Center Workers under the EEOICPA.

Clarksville Modification Center Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY 14214.

History:

During the 1950’s and 60’s, the Atomic Energy Commission (AEC) was responsible for maintaining, testing, and modifying nuclear weapons while the military was responsible for deploying these weapons.. One location the AEC carried out these responsibilities was at the Army base, Fort Campbell, located in Tennessee and Kentucky. The base had its own water and power treatment plants which made maintaining the secrecy of the presence of the nuclear weapons somewhat easier. In 1965, the AEC transferred all weapons out of Fort Campbell. More recently the DOE identified radioisotope contamination at several locations. The area today is open to Army personnel and their visitors. The use of the buildings at the Fort is varied and certain areas have been sealed off.

*NIOSH site profile:

SITE DESCRIPTION

The Clarksville Modification Center was one of 13 Weapons Storage Areas (WSAs) created under the Armed Forces Special Weapons Project. The Base was constructed in the mid- to late 1940s (the first weapon components arrived in July 1949) and supported by Sandia Corporation [now Sandia National Laboratories (SNL); for convenience, this Site Profile uses SNL throughout] for the AEC and the U.S. Navy. SNL, AEC, and the Navy were all active at Clarksville Modification Center from 1949 until 1958 performing maintenance and quality assurance on nuclear components of weapons. From 1958 until 1965, Mason and Hanger-Silas Mason Company, Inc. (MHSMC) operated Clarksville Modification Center for the AEC as a weapons modification and disassembly facility (Lamb Associates and Halliburton NUS 1996; McConn 2006; Mitchell 2003).

Clarksville Modification Center was originally separate from Fort Campbell, which was operated by the U.S. Army. In 1965, AEC activities transferred elsewhere, although the AEC was responsible for the Base through 1967. The Base was returned to the Army and incorporated into Fort Campbell in 1969 (Last, Gilmore, and Bronson 1998). It is unclear what activities occurred between 1967 and 1969 but storage of nuclear materials had ceased.

During the AEC tenure, nuclear weapons and weapon components were stored by the AEC and maintained by SNL and military personnel at the WSAs. WSAs consisted of storage buildings that housed nuclear capsules, maintenance structures, waste burial sites, and bunkers for storage of weapons casings. SNL personnel worked at Clarksville Modification Center under contract to the AEC until early 1962 (Lamb Associates and Halliburton NUS 1996; Last, Gilmore, and Bronson 1998; McConn 2006).

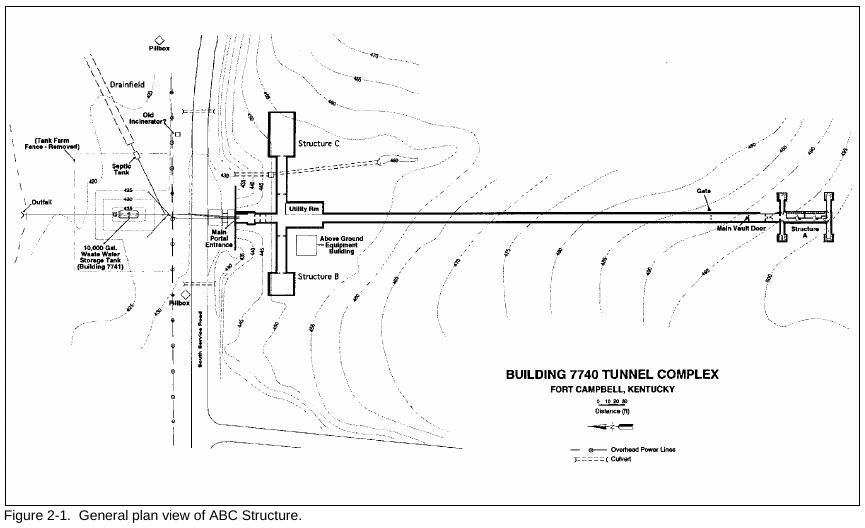

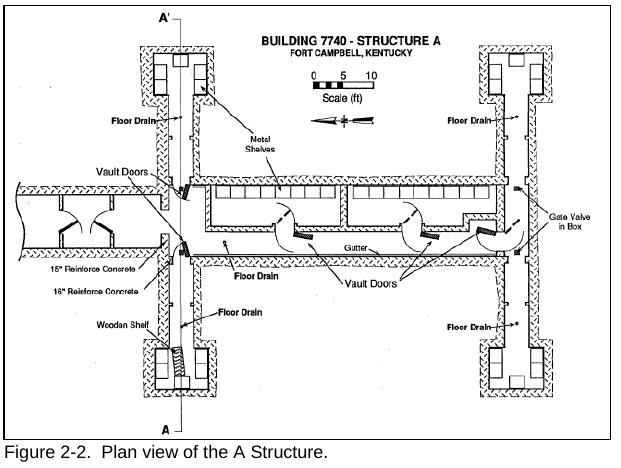

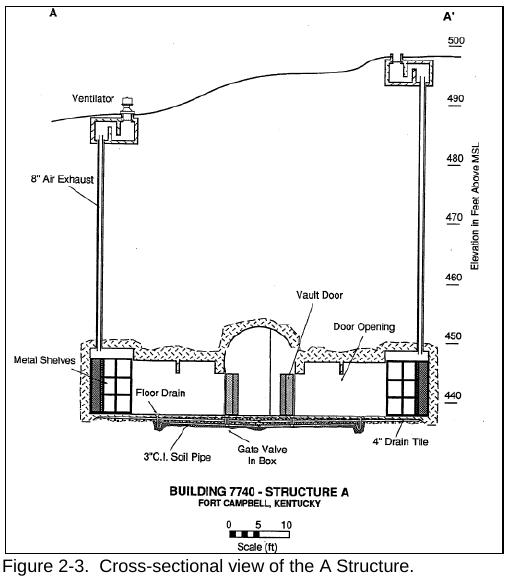

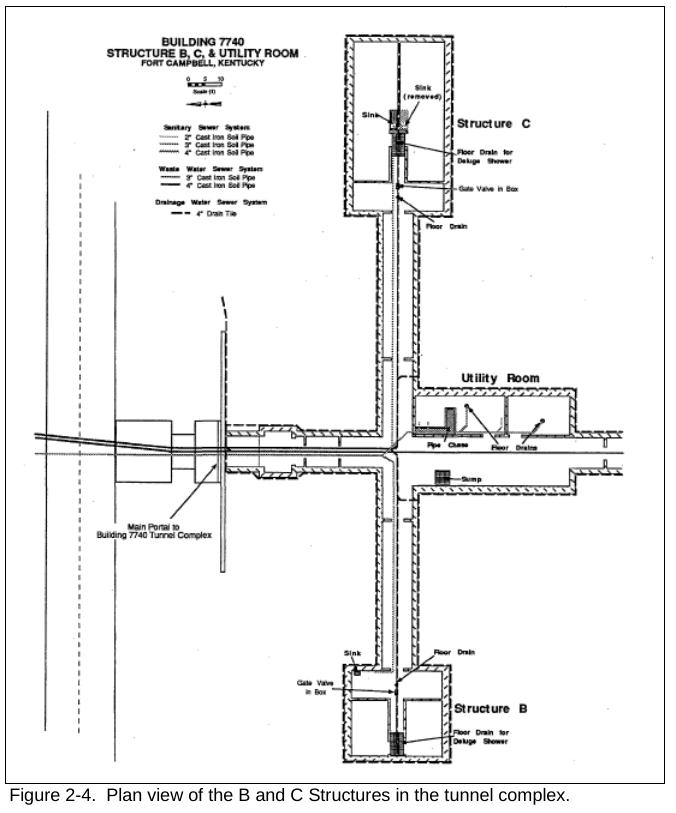

Storage of nuclear capsules at Clarksville Modification Center was in an underground complex known as the ABC Structure. The ABC Structure consisted of the “A” Structure, which was the nuclear capsule storage area that was secured behind a bank-type locking vault door at the end of a 600-ft- long tunnel; the “C” Structure, which was used for nuclear materials inspection and maintenance; and the “B” Structure, which was a backup facility for the C Structure but was used only as a medical wing. C Structure activities involved dismantling the nuclear assembly system, checking the activity of the fissile material, and replacing the polonium-beryllium (Po-Be) initiators (Lamb Associates and Halliburton NUS 1996; Last, Gilmore, and Bronson 1998; McConn 2006). Figure 2-1 is an overall plan view of the ABC Structure. Figure 2-2 shows a close-up plan view of the A Structure and Figure 2-3 shows a cross-sectional view. Figure 2-4 shows a plan view of the B and C Structures. [Figures 2-1 through 2-4 are from Last, Gilmore, and Bronson (1998); they refer to “Fort Campbell” because they were inactive facilities on Fort Campbell in 1998; however, at the time of use they were the

Clarksville WSA.]

A second C Structure, constructed in 1957, was an above-ground brick building used only to service non-nuclear components. Once this structure opened, the original C Structure ceased to be used due to moisture intrusion. In addition, the Clarksville WSA included a Gravel Gertie that was used for weapons maintenance and modification. The newer C Structure and Gravel Gertie had large overhead rails to support weapon subassemblies during maintenance. Standard above-ground igloos were used for storage, including the storage of sealed weapons. No nuclear maintenance activities occurred in these igloos (Lamb Associates and Halliburton NUS 1996; Last, Gilmore, and Bronson 1998; McConn 2006).

Some of the NIOSH Dose Reconstruction Project Computer-Assisted Telephone Interviews refer to the “bird cage.” This term was used officially to describe the criticality-safe framework built around a nuclear package (see Figure 2-5); however, the term appears to have been used unofficially to refer to the whole Clarksville Modification Center, meaning the fenced, heavily guarded area where an AEC Q-level clearance was required (more than just the tunnel complex).

SOURCE TERMS

Early weapons designs were of the in-flight insertable variety. Weapons of this type had removable nuclear capsules (also known as the physics package or pit) and were stored in a bird cage. The bird cage ensured storage in a criticality-safe manner. The capsules were pressure-sealed. Figure 2-5 shows a typical bird cage. The bird cages would hold the nuclear capsule, comprised of plutonium, highly enriched uranium (HEU), and Po-Be initiator. Periodic maintenance was required on these early weapon pits to exchange the Po-Be initiators due to the short half-life of 210Po. This would require disassembly of the weapon pit to remove the initiator, which was at the pit center.

Later weapon designs did not utilize the in-flight insertable concept or the Po-Be initiator, thereby eliminating the need to disassemble the weapon pit for modification. The Po-Be initiator was phased out over time, until 1956, and replaced by external neutron generators. The weapon pits are referred to as sealed pit designs. These designs included the potential for exposure to tritium. The introduction of tritium could have occurred as early as 1954 (McConn 2006; Mitchell 2003).

Another source of radioactive material used in early nuclear weapons was the spark gap tube. These tubes, which were part of the firing circuits, were used to switch large amounts of electrical current. A small amount of 137Cs was used in spark gap tubes to stabilize the electrical properties. These tubes, which were manufactured of thick glass to prevent breakage, would be a minor exposure pathway (McConn 2006).

As part of the maintenance activities, Clarksville personnel performed radiographs of the weapon components using a large 60Co source. The exact location of this source was not discovered but the newer C Structure is a likely candidate (McConn 2006).

In summary, the radioactive materials of interest at Clarksville Modification Center are tritium as a gas, weapons-grade plutonium, HEU, depleted uranium (DU; also used in weapons construction), 210Po in a Po-Be neutron initiator, a 60Co radiograph source, and small activities of 137Cs.

JOB DESCRIPTIONS

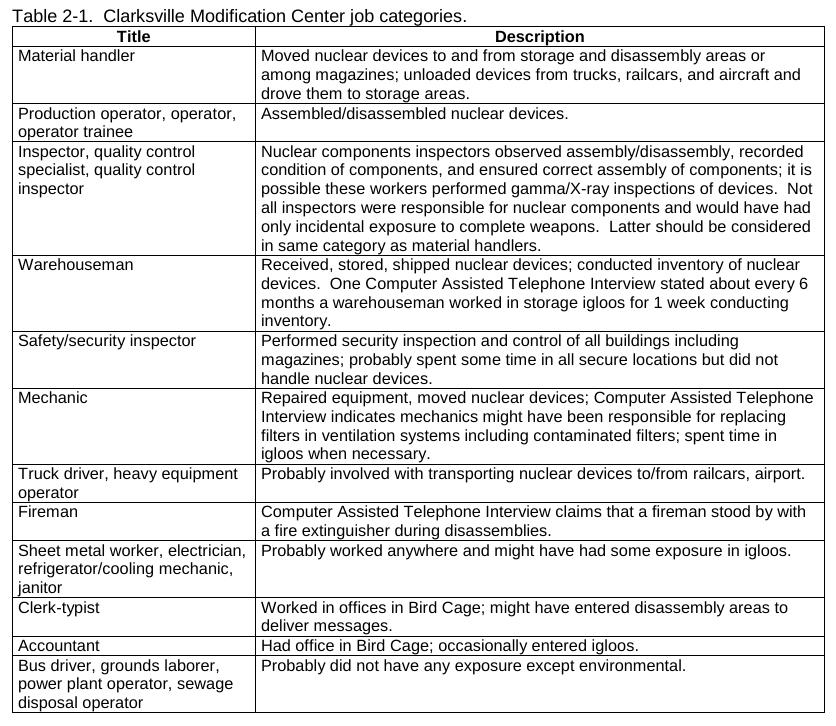

Table 2-1 lists job descriptions described in the claims files or by interviews of former employees (Bihl 2006a,b).

DOCUMENTS:

NIOSH SEC Evaluation Report:

Petition 202 (Jan 1, 1949 to Dec 31, 1967)

SEC Petition Evaluation Report – Petition SEC-00202 – Report Rev #: 0

Report Submittal Date: May 31, 2012

Technical Basis Documents

Site Profile for Clarksville Base Weapons Storage Area and Modification Center with Supplementary Guidance for Medina Base,