The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Titus Metals EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Titus Metals

Also Known As: Titus, Inc.

State: Iowa

Location: Waterloo

Time Period: 1956

Facility Type: Atomic Weapons Employer

Facility Description: Titus Metals performed the extrusion of uranium oxide billets into fuel plates for the Argonaut reactor at Argonne National Laboratory on June 29, 1956.

Listing:

Titus Metals is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

*Extrusion of Billets, Titus Metals, Inc., Waterloo, Iowa

A group of ANL employees consisting of LE. Walker and S. Matsas (MET), E. Leverens (SSE), K. C. Duffy'(SPM), and G. T. Lonergan (IHS), traveled to Waterloo, Iowa, on June 29 where they accomplished the extrusion of U308 billets into fuel plates for Argonaut.

Prior to beginning the extrusion operation, the floor area around the press, run-out table, stretch straightener, and all accessible portions of the press were surveyed. No activity was detected.

The floor area from the furnace (where the billets were heated) to the press was covered with a layer of vinyl approximately 48ft wide and topped with a layer of asbestos approximately 3s wide. When the actual extrusion operation began the covered floor area was designated a toe rubber area.

A one-gallon can half full of water was used to cool the dummy (pusher) block after each extrusion.

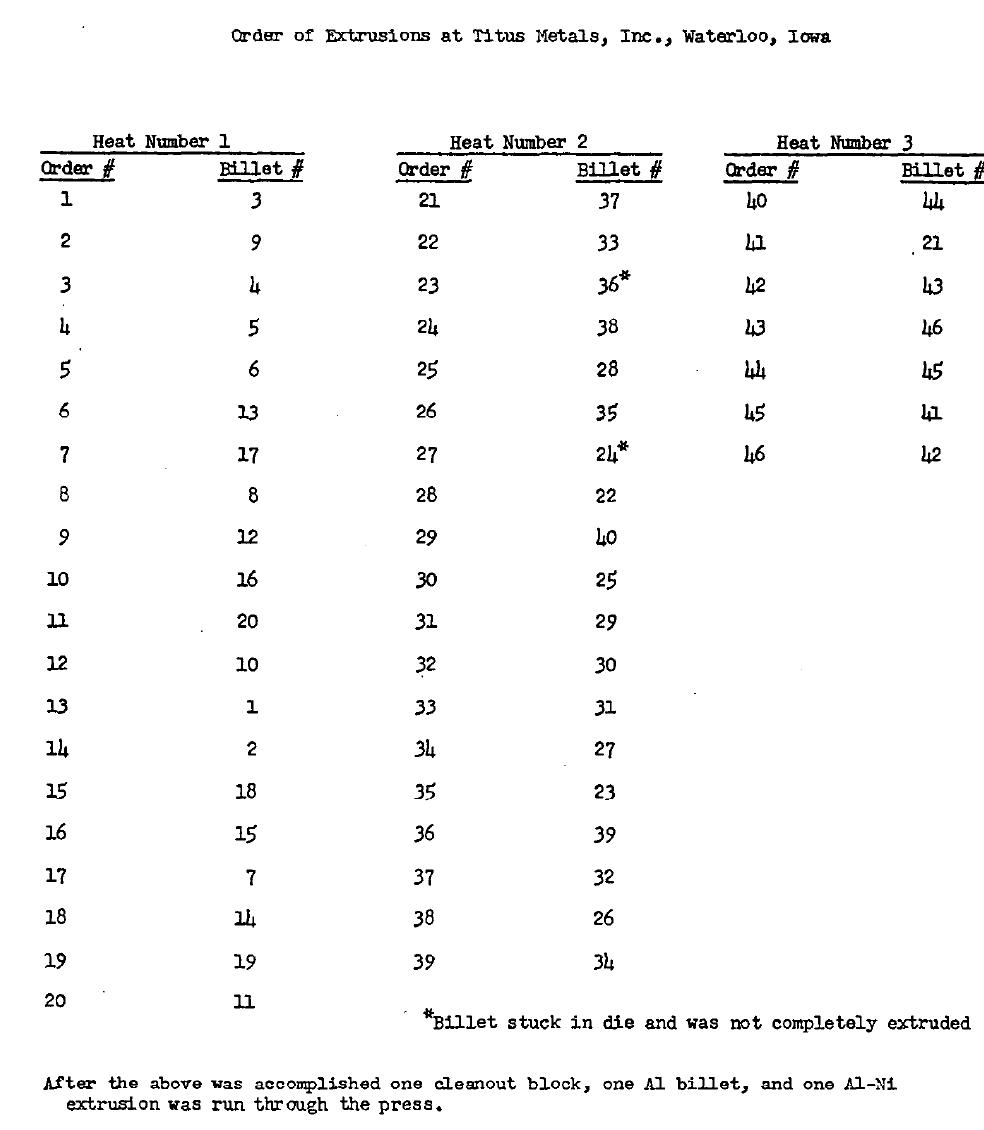

The extrusion operation was accomplished in three heats. The attached data sheet indicates the order of extrusion. Billets #36 and #24 in heat #2 were not completely extruded. In both instances the billet was

partly extruded leaving the die jammed. The unuextruded portion of the billet was removed and placed in a covered container as were all the unextruded portions of the billets and scraps. All tools used in clearing the die were surveyed and found to be free from contamination.

After the extrusion, stretch straightening, and packaging the plates was completed, another complete survey of the aforementioned floor areas and fixtures uas accomplished.

The asbestos on the floor directly in fmnt of the press uas contaminated in several spots to levels of 1M. All of the asbestos was rolled very carefully inside the vinyl plastic which uas underneath it. All

the plastic that uas used to cover the run-out table, stretch straightener table, cooling table, and other fixtures, was carefully folded and returned to ANL. No external. contamination was detected on the packages returned to ANL. None of the toe rubbers used in the operation was found to be contaminated.

The corrugated jaws of the stretch straightener aa well as the shears used to cut the butt of the extrusion from the extruded portion were found to be contaminated to levels of 20M. These items were’cleaned to

no activity detected by the Metallurgy parsonnel.

The pusher (dummy) block which MS too hot thermally to be surveyed at that time was returned to ANL where it was cleaned to no activity detected and returned to Titus Metals, Inc. The three dies that were used were Argonne property and returned to ANL. The die holder and die backer ring were returned to ANL to be cleaned prior to being returned to Titus Metals, Inc. The one-gallon can containing the water used to cool the pusher (dummy) block was also returned to ANL.

Smears were taken on the inside of the extrusion press cylinder. No contamination was detected on these smears with a portable instrument nor in an alpha scaler when so counted upon return to ANL. All accessible areas of the extrusion press were surveyed or smeared and no contamination was detected.

A survey of the shoes of the Titus Metals, Inc., employees who were actively engaged in the operation indicated no detectable contamination. The gloves, coveralls, and uork clothes of &ill persons actively engaged in the operation were bagged and returned to ANL for laundering.

In addition to the floor area and fixtures in the shop where the extrusion was accomplished, the offices, rest rooms, and clothes change areas were surveyed and no contamination was detected.

The floor sweepings and the brooms used to sweep the entire area after completing the operation were surveyed and no contamination was detected on or in either.

The extrusion operation was accomplished in such a manner that no contamination was detected at the Titus Metals, Inc. plant upon completion of the operation. This was possible only through the very careful hanging techniques and precautionary measures employed by the Metallurgy and Special Materials personnel.